Conformal Coating for electronics addresses several concerns which are environmental and operational factors affecting modern electronics. In the manner that it envelops the electrical parts protects them from the effects of moisture, dust, other chemicals, and varying temperatures. But how does this coating make a difference and provide the highest performance than any other coating type to have long-lasting? Let’s dive into this article to explore the benefits of conformal coatings for Electronics.

Environmental Protection of Conformal Coatings for Electronics

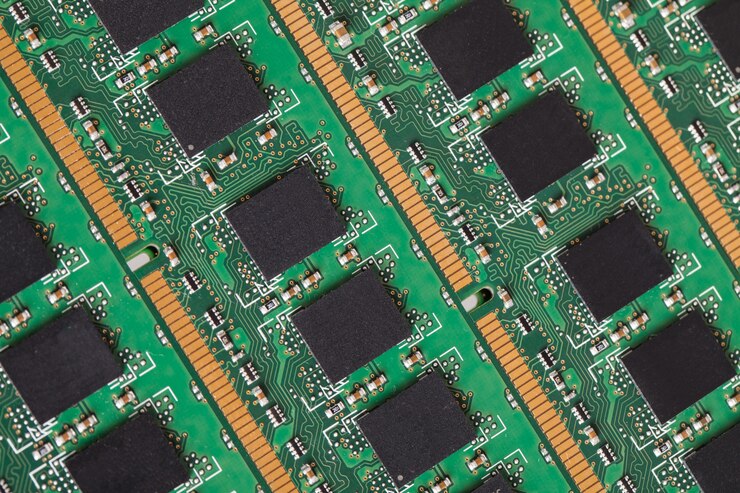

Electronics are vulnerable to different types of conditions for instance high humidity areas, dust or corrosive environments. Conformal coatings can also be considered as an insulating layer which shields sensitive components from contaminants. This guarantees that devices work to their optimum best especially when operating in complex environments and minimizes the incidences of failures.

The Role of Moisture Resistance in Enhancing Electronics Durability

In the circuits, moisture normally causes the effect of short-circuiting, corrosion or even total failure. Information concerning Moisture-resistant conformal coatings can be supplemented by the understanding that they are excellent barring moisture because they form a barrier against humidity. Marine, automotive, and aircraft industries some among them rely on this feature to ensure they maintain the reliability of their equipment.

Hydrophobic Coatings: A Game-Changer for Circuit Protection

Hydrophobic conformal coatings do not allow water molecule closeness hence non-conductivity and prevent the formation of electrical shorts or corrosion hence enhanced performance under wet conditions. While hydrophobic coatings focus on repelling moisture, conformal coatings also play a critical role in preventing corrosion caused by environmental exposure.

How Corrosion Resistance Extends the Lifespan of Electronics

Metals used in electronics corrode easily when exposed to oxygen, salt or any industrial chemical. Such reactions are avoided because these coatings help seal off metal surfaces. Not only does this help to increase the longevity of the devices, but probably their efficiency does not decrease over time.

Thermal Stability in Conformal Coatings for Maximum Efficiency

In elevated temperature conditions, electronic components are prone to degradation, leading to reduced performance or device failure. Heat-resistant conformal coatings with thermal stability protect these components by withstanding extreme thermal environments without compromising device functionality. This makes them indispensable in industries like aerospace, automotive, and industrial manufacturing, where electronic devices are routinely exposed to high temperatures.

How Conformal Coatings Provide Electrical Insulation

Short circuits between electrical contacts in devices can result in malfunctions or even hazardous failures. Conformal coatings offer superior electrical insulation, preventing circuit shorts and enhancing device safety. This feature is particularly critical in high-density electronics assemblies, where components are closely packed, and the risk of unintended connections is higher. By reducing these risks, conformal coatings improve both the reliability and efficiency of electronic devices.

Flexible Conformal Coatings: Resilience Under Mechanical Stress

Modern electronics often endure mechanical stress, vibrations, and frequent motion, especially in applications like automotive systems, aircraft electronics, and wearable technology. Semiflexible conformal coatings excel in these scenarios, providing durable protection without cracking or delaminating under stress. Their flexibility ensures long-lasting performance, safeguarding devices in environments where physical movement and vibrations are constant challenges.

Chemical Resistance Properties of Conformal Coatings in Industrial Applications

In industrial environments, chemical exposure can deteriorate electronic components. Conformal coatings shield these components, preserving their reliability and performance. These coatings shield against chemicals in preserving the performance and reliability of electronic devices. This feature is particularly appreciated in factories, laboratories and chemical plants.

Why UV-Resistant Coatings Are Essential for Outdoor Electronics

UV affects the electro-optical properties of many materials used in the fabrication of these devices and therefore affects the performance of the outdoor displays. Organic UV-resistant conformal coating covers the devices to guard them against wearing by the sun’s light. Such applications as solar, telecommunications, and outdoor sensors are among the many that can greatly benefit from this feature.

Precision Application Techniques for Conformal Coating Effectiveness

The effectiveness of conformal coatings depends heavily on precise application techniques Minerals coated today come with unique technologies such as newly developed selective coating machines that provide an even coat without the formation of overspray or leftover product. Such precision reduces the cost expenditure as much as it protects effectively hence enhancing the efficacy of the process.

The Future of Conformal Coatings: Innovations Shaping Electronics Protection

Relatively, innovation propels the future of conformal coatings. There are already Nano-coatings, bio-based solutions, and self-healing materials that are going to be developed to attend to the needs of advanced electronics. The progress and innovations here offer protection, environmental sensitivity and flexibility that are incomparable and mark new highs in endurance.

Final Thoughts

Coating Conformal is an essential resource for improving the life cycle of modern electronics. Ageing is overcome, corrosion is avoided, it exhibits thermal and mechanical shock, and these uses cut across industries and markets. Modern technologies are constantly developing along with conformal coatings and that’s why they are still relevant to electronic protection. Thus, the adoption of such solution will help organizations improve the performance of their products, lower the costs of maintenance of such devices and increase the confidence of customers due to the reliability and sturdiness of particular products.

By adopting conformal coatings, organizations can boost product reliability, reduce maintenance costs, and enhance customer confidence. Contact us today to learn more about implementing these solutions for your business.