Manufacturing has come a long way from manual processes and basic assembly lines. Today, products are expected to be smarter, faster, and more reliable — and delivered at record speed. That’s why test engineering and automatic test development have become essential components in modern manufacturing. At Qual-Pro, we specialize in providing cutting-edge test engineering solutions and automated test development services, ensuring your products meet the highest standards of quality and performance while accelerating time-to-market.

Whether you’re producing electronic components, medical devices, or automotive parts, testing isn’t just a final step — it’s part of the entire production journey. In this article, we’ll break down what test engineering is, how automated testing works, and why both are vital to producing high-quality, error-free products at scale.

What Is Test Engineering?

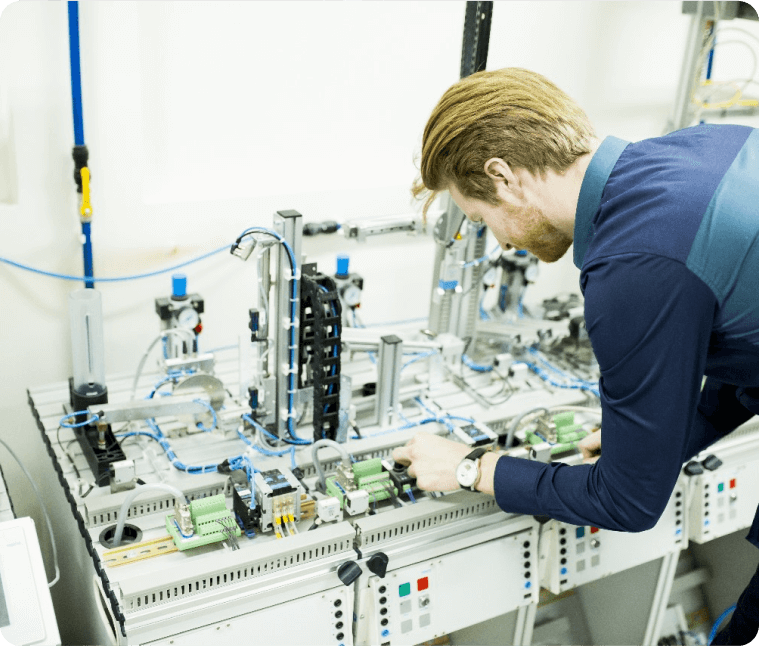

Test engineering is all about making sure that what you produce works the way it’s supposed to — every single time. It involves designing tests, creating test procedures, and setting up the systems that check for flaws in hardware and software before the product ever reaches the customer.

Think of test engineers as the detectives of the manufacturing world. Their job is to find and solve problems — or better yet, prevent them altogether. They work closely with design and production teams to ensure quality isn’t an afterthought, but baked into the process.

Some common tasks in test engineering include:

- Designing custom test equipment

- Creating testing protocols and procedures

- Developing automated test scripts

- Troubleshooting test failures

In short, they’re the folks making sure your smartphone turns on, your car’s electronics don’t glitch, and your smart watch doesn’t crash after an update.

What Is Automatic Test Development?

Automatic test development takes the work of test engineering to the next level. Instead of manually running every test, engineers build systems and scripts that can automatically test devices or components in real-time.

Why is this important? Because modern manufacturing runs at lightning speed. Testing hundreds or thousands of units by hand simply isn’t practical anymore. Automation allows manufacturers to:

- Increase test coverage

- Reduce human error

- Speed up production

- Catch issues earlier

Automatic testing systems are especially critical in sectors like electronics manufacturing, where a single faulty solder or misaligned chip could mean a product failure.

Why Are These Practices So Important in Manufacturing?

Ensuring Product Quality

Let’s face it: no customer wants to deal with defective products. A small oversight in testing can result in product recalls, safety issues, and major brand damage. Test engineering ensures that only products that pass rigorous checks reach the end user.

Automated tests make it easier to maintain consistent quality across high volumes of production, reducing variability and increasing reliability.

Speeding Up Production Timelines

In a competitive market, speed matters. Automated testing allows manufacturers to identify and fix issues on the fly, reducing bottlenecks and keeping production lines running smoothly.

When tests are integrated early into the manufacturing process (also known as Design for Testability), it becomes much easier to debug issues without slowing everything down.

Reducing Costs

Catching a defect early is significantly cheaper than fixing a product after it’s been shipped. Poorly tested products can lead to costly reworks, returns, and even legal liabilities.

With test engineering and automation, you avoid costly surprises and ensure that your product meets all performance and regulatory standards the first time.

Improving Traceability and Data Insights

Automated test systems collect tons of data. This data can be used to improve product designs, identify recurring failures, and make informed decisions about production.

Need to know which batch of devices had the highest failure rate? Or which component is causing the most issues? Automated testing gives you those answers.

Boosting Customer Satisfaction and Brand Trust

Quality products lead to happy customers. If your devices or parts perform consistently well, your brand earns a reputation for reliability.

Test engineering and automation contribute directly to that consistency. Customers may not see the behind-the-scenes testing work — but they’ll definitely notice when something works flawlessly right out of the box.

Real-World Examples of Test Engineering and Automatic Test in Action

Electronics Manufacturing

In PCB assembly lines, automated optical inspection (AOI) systems and in-circuit testers (ICT) check for misplaced components, shorts, and solder defects. These systems run thousands of checks per second, far faster than any human could.

Automotive Industry

From infotainment systems to airbag sensors, automotive components go through exhaustive testing before they’re approved for road use. Test engineers develop stress simulations, environmental tests, and safety checks that comply with international safety standards.

Medical Devices

There’s no room for error when it comes to life-saving equipment. Test engineers build custom fixtures and run functional verification tests to ensure everything from heart monitors to diagnostic tools performs reliably.

How to Implement Test Engineering in Your Manufacturing Process

If you’re in manufacturing and not already using test engineering principles, now’s the time to start. Here are a few steps to get you going:

Involve Test Engineers Early Include test engineers during product design to build testability into your components and assemblies.

Design for Automation Plan for automated test points and fixture compatibility in your products from the start.

Invest in Scalable Testing Tools Choose test platforms and equipment that can grow with your production line.

Develop a Feedback Loop Use the data from your automated tests to continuously improve product design, supplier quality, and manufacturing processes.

Final Thoughts

At the end of the day, manufacturing is about producing reliable products at scale. Test engineering and automatic test development are the cornerstones that make that possible. They don’t just find problems — they prevent them. And in a world where reputation, quality, and speed can make or break your business, that kind of assurance is priceless.

So whether you’re building the next big tech gadget or a life-saving medical device, make sure you’ve got a solid test strategy in place. It could be the difference between a product