Acrylic conformal coating is a widely used protective layer applied to printed circuit boards (PCBs) and electronic components to safeguard them from environmental factors such as moisture, dust, chemicals, and temperature variations. This transparent polymeric film enhances the reliability and longevity of electronic devices by providing a barrier that prevents corrosion, electrical shorts, and other forms of damage.

Key Benefits of Acrylic Conformal Coating

Moisture Protection

One of the primary reasons to use acrylic conformal coating is its excellent moisture resistance. Moisture can lead to corrosion, short circuits, and other failures in electronic components. Acrylic coatings act as a barrier, preventing moisture from reaching sensitive areas of the PCB, thereby enhancing the reliability and longevity of the device.

Electrical Insulation

Acrylic conformal coatings provide effective electrical insulation, which is crucial for preventing current leakage and short circuits. This insulation ensures that the electronic components operate as intended without interference from external electrical sources.

Ease of Application and Rework

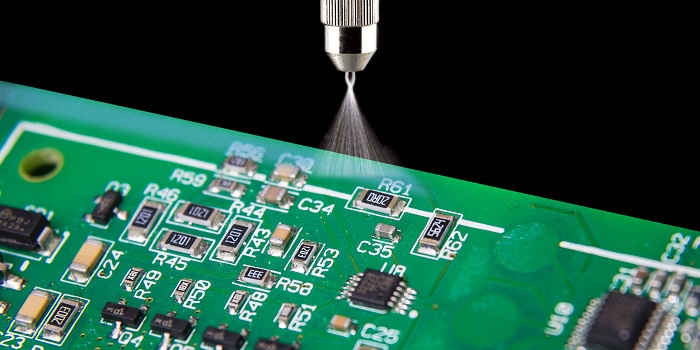

Applying acrylic conformal coating is straightforward and can be done using various methods such as brushing, spraying, dipping, or robotic techniques. This versatility allows for flexibility in different manufacturing environments. Moreover, if repairs or modifications are needed, acrylic coatings can be easily removed with appropriate solvents, facilitating efficient rework processes.

Fast Drying Time

Acrylic coatings cure rapidly at room temperature, typically reaching optimal physical properties within minutes and fully curing in less than an hour. This quick drying time accelerates the production process, leading to faster turnaround times and increased manufacturing efficiency.

Cost-Effectiveness

Due to their ease of application and rapid curing, acrylic conformal coatings are cost-effective solutions for protecting electronic assemblies. The reduced need for expensive equipment and the ability to perform rework without significant additional costs contribute to the overall affordability of using acrylic coatings.

Transparency for Visual Inspection

Acrylic coatings are typically transparent or translucent, allowing for visual inspection of the underlying components without the need to remove the coating. This transparency aids in quality control processes, enabling manufacturers to detect defects or issues in the assembly without compromising the protective layer.

Fungus Resistance

Acrylic conformal coatings offer resistance to fungal growth, which is particularly important in humid environments where such growth can lead to performance degradation. This property ensures that electronic devices maintain their functionality even in challenging environmental conditions.

High Dielectric Strength

Acrylic coatings possess high dielectric strength, making them suitable for applications requiring electrical insulation. This characteristic helps in preventing electrical arcing and ensures the safe operation of electronic components under varying voltage conditions.

Minimal Shrinkage During Curing

During the curing process, acrylic coatings exhibit minimal shrinkage, which helps in maintaining the integrity of the protective layer and ensures consistent coverage over the entire surface of the PCB. This property is crucial for maintaining the uniformity and effectiveness of the coating.

Environmental Considerations

Modern acrylic conformal coatings are designed to be environmentally friendly, with formulations that are low in volatile organic compounds (VOCs) and free from ozone-depleting substances. This makes them a more sustainable choice compared to some other coating materials, aligning with global efforts to reduce environmental impact.

Comparison of Conformal Coating Materials

| Property | Acrylic (AR) | Urethane (UR) | Silicone (SI) | Epoxy (EP) |

|---|---|---|---|---|

| Moisture Resistance | Excellent | Good | Excellent | Fair |

| Electrical Insulation | High | High | Moderate | High |

| Chemical Resistance | Fair | Excellent | Excellent | Excellent |

| Ease of Application | Easy (brush, spray, dip) | Moderate (requires mixing) | Moderate (requires mixing) | Difficult (requires mixing) |

| Reworkability | Easy (removable with solvents) | Difficult (requires solvents) | Difficult (requires solvents) | Difficult (requires solvents) |

| Curing Time | Fast (room temperature) | Moderate (room temperature) | Slow (requires heat) | Slow (requires heat) |

| Cost | Low | Moderate | High | Moderate |

Considerations When Using Acrylic Conformal Coating

While acrylic conformal coatings offer numerous advantages, it’s important to consider certain limitations:

- Chemical Resistance: Acrylic coatings may not offer sufficient resistance to aggressive chemicals or solvents. In applications where exposure to such substances is expected, alternative coatings like urethane or silicone may be more suitable.

- Temperature Limitations: Acrylic coatings typically have a lower operating temperature range compared to other coatings. For high-temperature applications, it’s essential to ensure that the acrylic coating can withstand the operating conditions.

- Mechanical Protection: While acrylic coatings provide some level of mechanical protection, they may not be as effective as other coatings in applications subject to high mechanical stress or abrasion.

Conclusion

In summary, using acrylic conformal coating offers a range of benefits, including superior moisture protection, electrical insulation, ease of application and rework, fast drying times, cost-effectiveness, transparency for visual inspection, fungus resistance, high dielectric strength, minimal shrinkage during curing, and environmental considerations. These advantages make acrylic conformal coatings a preferred choice for protecting electronic assemblies in various industries.