In today’s electronics-driven world, efficiency, miniaturization, and reliability are more critical than ever. At the heart of modern electronic circuit design lies the Surface Mount Device (SMD) — a revolutionary component that has transformed how circuit boards are manufactured and assembled. From smartphones and medical equipment to automotive systems and industrial machines, Surface Mount Device technology is the backbone of today’s advanced electronics.

This article explores the essentials of Surface Mount Device technology, how it improves performance, the components involved, its benefits, applications, and how businesses can choose the right solution for their manufacturing needs.

What is a Surface Mount Device?

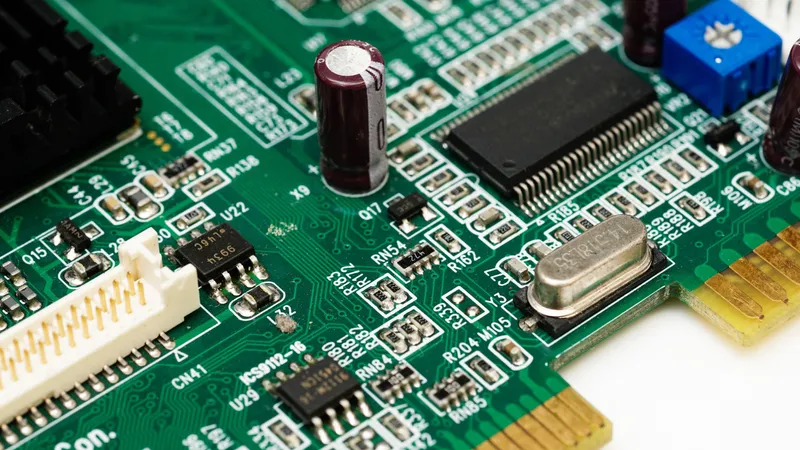

A Surface Mount Device refers to an electronic component that is designed to be mounted directly onto the surface of a printed circuit board (PCB), as opposed to older through-hole components that required leads to be inserted through drilled holes.

Surface Mount Technology (SMT) enables the use of SMDs, allowing for more compact, lightweight, and high-performance electronic devices. These components typically include resistors, capacitors, diodes, transistors, and integrated circuits—all in significantly smaller packages than their traditional counterparts.

Why Surface Mount Device Technology Matters

The global electronics industry thrives on innovation and efficiency. The rise of Surface Mount Device solutions has enabled manufacturers to build smaller, faster, and more reliable products at scale. Here are some reasons why this technology is indispensable:

1. Space Efficiency

One of the key benefits of using a Surface Mount Device is its small size. This allows manufacturers to place more components on each board, making it perfect for miniaturized circuits and compact product designs.

2. High-Speed Assembly

With the advent of automated soldering and robotic pick-and-place machines, SMDs allow faster production times and reduced manual labor. This not only improves throughput but also minimizes human error.

3. Improved Performance

Due to shorter lead lengths and tighter electrical paths, Surface Mount Devices offer better high-frequency performance and reduced signal interference compared to traditional components.

4. Cost-Effective Production

Although the initial setup for SMT components may involve investment in specialized equipment, long-term production is generally more cost-efficient due to lower labor costs and fewer materials used in assembly.

Types of Surface Mount Devices

There are various kinds of SMDs designed to meet specific electrical functions. Here are the most commonly used types:

– Passive SMDs

These include resistors, capacitors, and inductors. They’re generally rectangular and come in various sizes depending on their capacity and power ratings.

– Active SMDs

Active devices include diodes, transistors, and ICs (Integrated Circuits). They play a more complex role in signal processing, amplification, and computing tasks.

– Optoelectronic SMDs

These include light-emitting diodes (LEDs), photodiodes, and optocouplers. These components manage light-based signal transmission in devices like fiber optics and displays.

The Role of Surface Mount Devices in PCB Manufacturing

During PCB manufacturing, the choice of components and their placement directly impacts a device’s overall performance and reliability. Here’s how Surface Mount Devices are integrated into the PCB assembly process:

1. Design and Layout

PCB designers utilize high-density interconnects (HDI) to plan the optimal layout for placing multiple SMDs in tight spaces without electrical interference.

2. Solder Paste Application

Solder paste is applied to the board’s pads using a stencil. This step ensures a reliable connection between the PCB and the Surface Mount Devices during reflow soldering.

3. Pick-and-Place Assembly

Using automated machines, SMT components are accurately placed on the board. These machines can handle thousands of placements per hour with micron-level precision.

4. Reflow Soldering

The board is passed through a reflow oven where the solder paste melts and bonds the components to the PCB. This step is crucial for ensuring a reliable, electrically sound connection.

Advantages of Using Surface Mount Devices

Choosing Surface Mount Devices over traditional through-hole components offers several distinct advantages:

✅ Higher Component Density

SMDs enable the design of compact, multi-layered PCBs which support more features in smaller footprints—critical for modern gadgets.

✅ Lower Inductance and Resistance

Their small size and lack of lead wires reduce resistance and parasitic inductance, improving performance in high-frequency applications.

✅ More Reliable Connections

Reflow soldering ensures consistent and robust connections, reducing the risk of failures due to vibration or mechanical stress.

✅ Efficient Thermal Performance

SMDs can dissipate heat more effectively due to their tighter placement and shorter pathways, preventing overheating and prolonging lifespan.

Applications of Surface Mount Devices

Thanks to their size, performance, and reliability, Surface Mount Devices are widely used across numerous industries:

📱 Consumer Electronics

Smartphones, tablets, laptops, and wearables all rely heavily on SMD-based electronic assembly to meet user expectations for speed and portability.

🚗 Automotive Systems

From advanced driver-assistance systems (ADAS) to infotainment and sensors, vehicles today are packed with electronics that depend on surface mount technology.

💉 Medical Equipment

Devices like portable diagnostic machines, monitoring systems, and imaging equipment use Surface Mount Devices for precision, safety, and compact design.

🌐 Telecommunications

Network devices and signal processors use SMDs to enable high-speed data processing and reliable connections.

🏭 Industrial Automation

Robotics, control panels, and sensors in automated environments use SMDs to meet strict performance and durability requirements.

Challenges and Considerations

While Surface Mount Devices offer many benefits, they also introduce specific challenges:

- Thermal Stress: Improper soldering can lead to cracking or component detachment.

- Inspection Complexity: Due to their small size, defects are harder to detect visually, requiring AOI (Automated Optical Inspection) or X-ray inspection.

- Rework Difficulty: Manual rework of SMDs is labor-intensive and requires specialized tools and experience.

Therefore, choosing the right manufacturing partner or in-house equipment for surface mount device assembly is crucial for long-term success.

How to Choose the Right Surface Mount Device Solutions

When selecting a provider or equipment for Surface Mount Device assembly, consider the following:

🔧 Technical Capability

Look for a partner that offers state-of-the-art pick-and-place systems, reflow ovens, and inspection technologies to ensure consistent quality.

📊 Experience in Your Industry

Different sectors have specific compliance and performance requirements. Choose a vendor familiar with the standards in your field.

📦 Production Volume Support

Whether you’re a startup with low-volume needs or a large corporation seeking mass production, your provider should scale with you.

✅ Quality Assurance

Certifications like ISO 9001 or IPC standards are signs of a reliable manufacturing process for electronic assembly.

Conclusion

In the fast-paced world of electronics, choosing the right Surface Mount Device solution can significantly affect your product’s performance, size, and cost. Whether you’re designing compact wearables or robust industrial machines, SMD technology provides the efficiency and precision needed for modern innovation.

At Qual-Pro, we deliver high-performance Surface Mount Device solutions tailored to meet your exact specifications. Our advanced manufacturing processes, quality control, and technical expertise ensure that every assembly performs with reliability and consistency. Trust us to help bring your next-generation electronic products to life—efficiently and accurately.