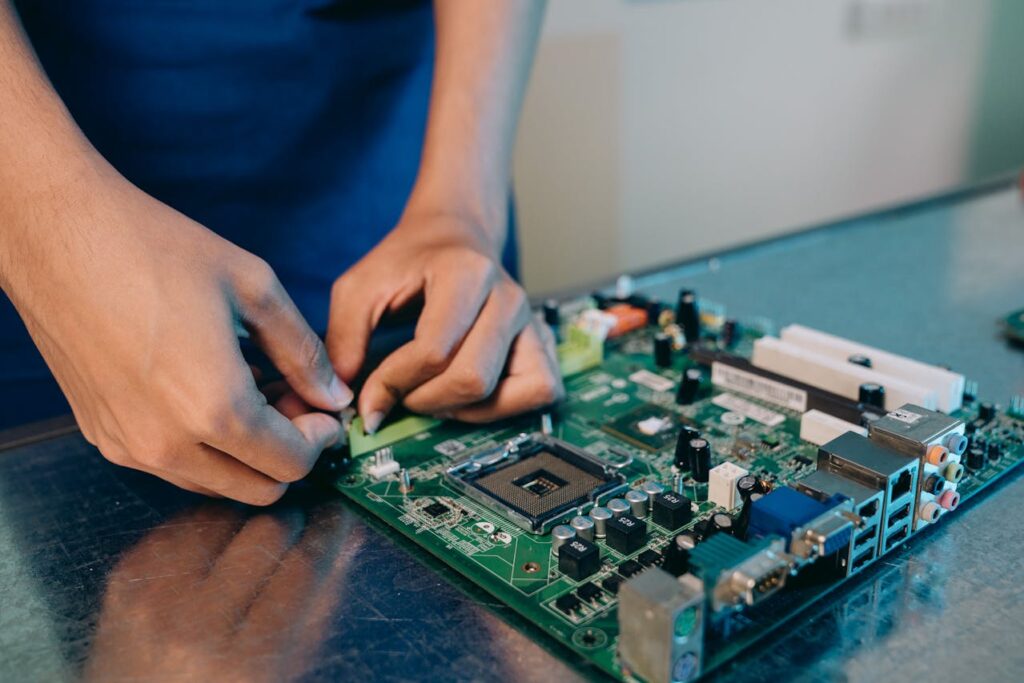

Printed Circuit Board Assembly (PCBA) translates simple elements into circuits that operate hundreds of today’s electronics. Since adding components such as resistors, capacitors, microchips and other elements on a single printed circuit board (PCB), PCBA makes it possible to run the world, literally, from a smartphone to life support medical equipment. It has drastically transformed how electronics are produced significantly making production to be efficient, reliable and scalable in the manufacturing process.

In What Way has PCBA affected the Electronics Industry?

The integration of PCBA has revolutionised the manufacturing process of electronics as bulky, hand-wired circuits have been discontinued and replaced with small, efficient circuits. This evolution has enabled manufacturers to develop scalable compact, efficient and faster devices. Further, PCBA fosters the idea of rapid prototyping where the rate of production accelerates resulting in increased market expansion since new products can be developed rapidly.

What are the Stages of PCBA? – A Detailed Analysis of Its Design and Production

Component Placement: Automations correctly orient and fix parts on the surface of a PCB board in a manner that has been planned earlier.

Soldering: Components are connected with the help of conventional or complicated waveform/ reflow soldering techniques.

Inspection and Testing: Laser vision and functional testing guarantee the management that each board is functioning properly and as it was designed.

Final Assembly: The use of the finished PCBA is in the integration of a PCBA into the device.

Explaining this in detail is why PCBA has emerged as a keystone in the manufacturing of modern electronics.

How do automation and technology support PCBA?

More to this, automation has helped take PCBA to enviable levels by enhancing accuracy and minimizing human intervention. High-speed automatic printers guarantee the right placement of components using pick-and-place robots while automated optical inspection equipment (AOI) identifies the slightest of flaws. This has in turn led to improved quality in the assemblies as well as improved rates of production to feed the ever-increasing international demand for electronics.

Why is PCBA the future of miniaturized Electronics?

PCBA is a leading concept due to the emergence of the trend of the miniaturization of portable devices by consumers. PCBs are able to pack a large number of circuits into a small, printed area; thus, manufacturers can produce smaller, yet effective electronic devices. This transition is not insignificant to the general consumer market, but more importantly useful in industries such as aerospace and medial where size is a critical factor.

In what manner does PCBA function to increase product reliability?

Reliability is always a crucial element when it comes to electronics, and through value-added PCBA assembly, such a product delivers reliable performance. It is necessary to use high-quality materials to assemble devices, solder precisely, and test items for endurance to environmental challenges. This focus has made PCBA ideal especially for industries that require reliability and durability include automotive, defence and health care industries.

Help organize CircuitNet and learn how PCBA supports sustainable electronics manufacturing.

Sustainability is the new watchword in the manufacturing market and PCBA is already on the frontier of embracing the culture.

PCBA continuously seeks ways to cut down its usage of materials and wastes through using automated processes. Moreover, the development of lead-free solder and reusable printed circuit board materials corresponds with the global initiative in the creation of green electronics and guarantees that the industry is developing sustainably.

However, the following are some of the problems experienced by players in the PCBA industry; Shortage of components the, high initial cost of setting up a PCBA manufacturing company and the issue of quality when manufacturing products in large quantities.

Nevertheless, these challenges are being overcome by the manufacturers in the following ways; Efficient supply chain, better investments on the sophisticated equipment, strict quality control mechanism. All these strategies help PCBA to sustain itself within the relevant market that is characterized by constant growth of innovation and demands.

Lets Wrap Up!

Broad fields like IoT, AI, and 5G have a strong relation with advanced PCBA techniques. The assembly process also enables the formation of sophisticated and compact circuits that enable intelligent appliances, driverless systems, and next-generation networks. With each passing day, new technologies are developed and PCBA stays ahead of its game by spearheading the development of new innovations that will lead to their creation.

Printed Circuit Board Assembly is greater than a manufacturing method that shapes the production of present electronic equipment – it is a change agent. Through streamlining the future production, improving its reliability and supporting innovative developments, PCBA has transformed electronics manufacturing and will carry on pushing the industry forward. Whether as the enabler for miniaturized designs, and sustainability practices or as the fundamental platform for technologically advanced circuitry; PCBA is without doubt the backbone of electronics manufacturing today.