In the high-stakes world of modern aviation and space exploration, the pressure to innovate while ensuring safety and reliability has never been greater. At the heart of this technological revolution is Aerospace Electronics Manufacturing—a specialized industry responsible for crafting the critical systems that power everything from commercial aircraft to satellites and military jets.

The increasing complexity of avionics systems and the growing expectations for performance and reliability place unique demands on electronics manufacturers in this space. Whether it’s the navigation system of a fighter jet or the communication module of a weather satellite, the bar for precision, durability, and quality is set extraordinarily high.

What Makes Aerospace Electronics Manufacturing Unique?

Unlike commercial electronics, which can afford some margin for error, Aerospace Electronics Manufacturing deals exclusively with mission-critical systems. A single failure in a flight control system or communication unit can result in catastrophic consequences. Therefore, manufacturers must meet stringent aerospace standards, such as AS9100, IPC Class 3, and NASA-STD-8739, to ensure product integrity.

The industry is also characterized by its heavy investment in rigorous testing protocols, extreme environmental simulations, and long-term component reliability analysis. These elements are baked into every stage—from design to final quality assurance.

Meeting the Challenges: Precision, Compliance, and Innovation

1. Design for Reliability

The first step in delivering top-tier aerospace electronics lies in the design phase. Engineers must consider not only the functional requirements but also environmental factors such as temperature extremes, radiation, vibration, and pressure differentials. Components used in Aerospace Electronics Manufacturing often include redundant systems to ensure continuous operation in case of partial failures.

Additionally, component traceability is a critical aspect of design and supply chain strategy. Every resistor, capacitor, or IC must have a documented origin and lifecycle assessment to meet aerospace standards.

2. Advanced PCB Assembly for Aerospace

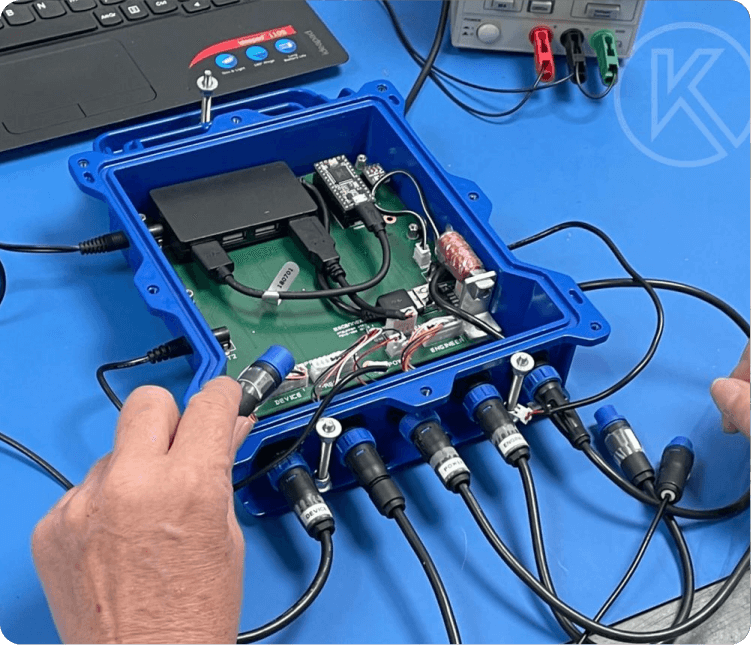

The complexity of PCB assembly for aerospace applications cannot be understated. These boards must support high-speed data transfer, EMI shielding, and mechanical stress resistance, all within compact layouts. Multi-layer, high-density interconnect (HDI) PCBs with controlled impedance are often used to meet these demands.

Moreover, the soldering processes—whether through-hole or surface mount—must adhere to cleanroom standards to eliminate any risk of contamination that could affect circuit performance.

3. Extreme Environmental Testing

Testing is not just a final step; it is integrated throughout the manufacturing lifecycle. From thermal cycling and humidity exposure to vibration and shock testing, every product must prove its resilience under the harshest conditions. For Aerospace Electronics Manufacturing, such testing is essential for both defense and space electronics, where equipment might operate hundreds of kilometers above the Earth’s surface or in combat zones.

Testing protocols often include:

- Burn-in testing

- HALT (Highly Accelerated Life Testing)

- HASS (Highly Accelerated Stress Screening)

- Conformal coating inspection

4. Compliance and Quality Assurance

Meeting aerospace compliance requirements goes beyond ticking boxes—it is a culture embedded into every level of Aerospace Electronics Manufacturing operations. Certification to global standards like AS9100 ensures that quality management systems are in place, but continuous improvement is also a driving force. Many top-tier manufacturers integrate real-time data tracking, machine learning algorithms for defect prediction, and Six Sigma methodologies to refine their output.

5. The Role of Supply Chain Management

Because aerospace projects often span years and involve global stakeholders, managing the supply chain becomes another complex task. Delays or shortages in components can halt entire programs. That’s why Aerospace Electronics Manufacturing companies often build strategic relationships with trusted suppliers and maintain contingency plans.

This is especially critical in sourcing mil-spec components and ensuring compatibility with legacy systems, a frequent challenge in defense and aerospace contracts.

Future Outlook: The Rise of AI and Automation

As technology continues to evolve, so too does Aerospace Electronics Manufacturing. The rise of artificial intelligence (AI), machine learning, and industrial IoT is beginning to revolutionize the production floor. Smart factories with predictive maintenance capabilities, robotic assembly arms, and real-time quality analytics are reducing human error and improving throughput.

In the coming years, innovations such as additive manufacturing (3D printing of electronics), quantum computing interfaces, and autonomous aerospace systems will further elevate the importance and complexity of the electronics that keep aircraft and spacecraft running.

Conclusion

Meeting the demands of Aerospace Electronics Manufacturing is not a matter of simply following protocol—it’s about rising to the challenge of creating highly reliable, precisely engineered systems that must perform under the most demanding conditions imaginable. From avionics systems and defense and space electronics to PCB assembly and environmental testing, every element of the process must align with the uncompromising expectations of the aerospace industry.

As the world becomes more reliant on advanced aerospace technologies for communication, defense, exploration, and transportation, the role of high-reliability electronics will only grow. And those manufacturers who can meet these demands with excellence, innovation, and precision will lead the way in shaping the future of flight and space.