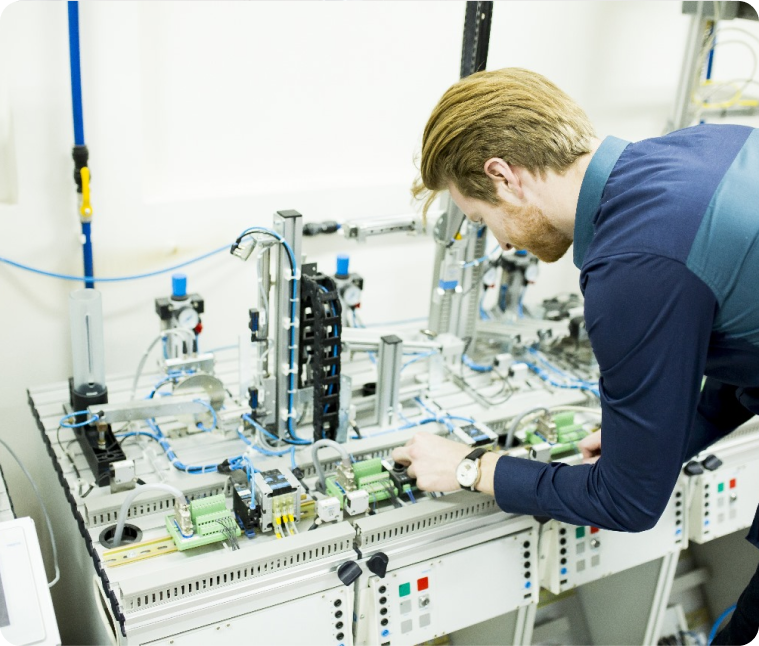

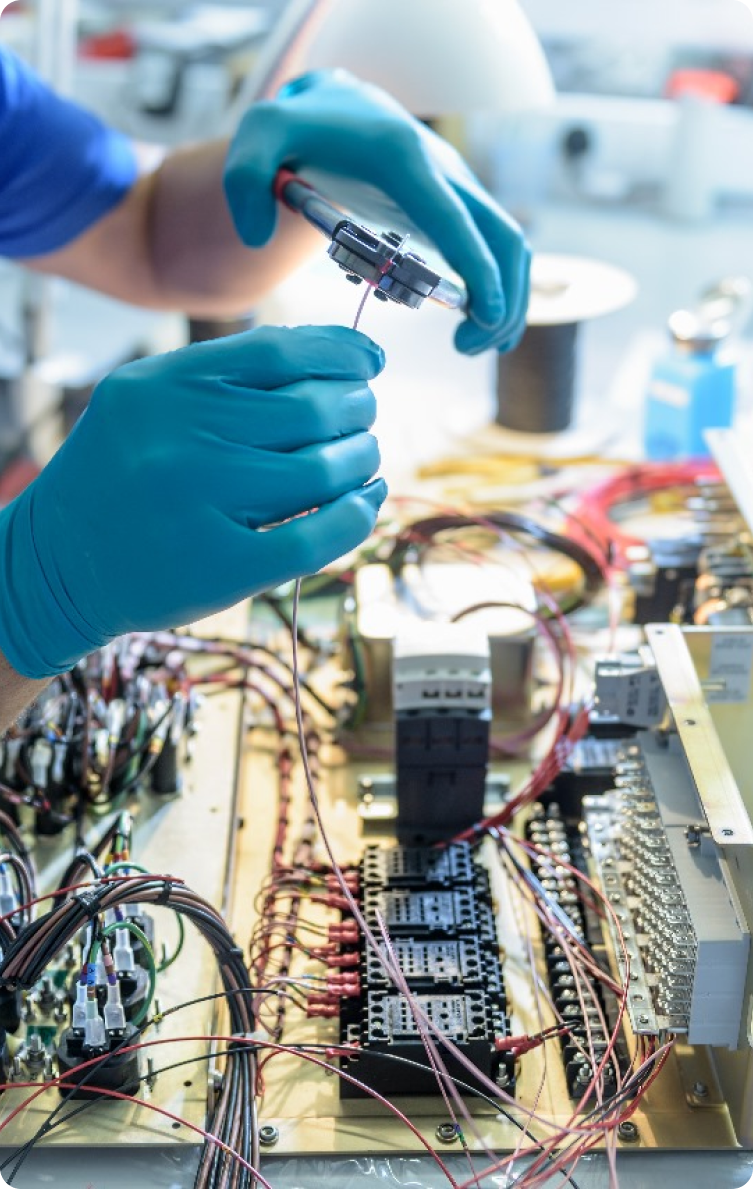

We make sure your electronics work perfectly. We test them thoroughly and create special computer programs to check them automatically.

Don’t let faulty products derail your success. Qual-Pro’s expert Test Engineering and Automatic Test Development services guarantee your electronics perform flawlessly, meet stringent industry standards, and reach the market faster. Our comprehensive electronics testing services meticulously examine every aspect of your product, from individual components to complete assemblies, ensuring peak performance and unwavering reliability. With over 50 years of experience and a commitment to excellence, Qual-Pro is your trusted partner in achieving manufacturing success.

Ensure your products perform flawlessly under any condition. Our comprehensive testing services guarantee quality, compliance, and customer satisfaction.

In the realm of electronics, even the smallest defect can have major consequences. That’s why rigorous testing is crucial for every product, from concept to launch.

The Importance of Thorough Testing

Thorough testing is not just a checkbox; it’s the foundation of product excellence. It acts as a safety net, catching potential flaws before they snowball into costly problems like product recalls, warranty claims, and irreparable damage to your brand’s reputation. By identifying and rectifying defects early on, testing ensures that your product delivers on its promises, meeting the highest standards of quality and reliability. Research by the National Institute of Standards and Technology (NIST) indicates that the cost of addressing a defect multiplies exponentially at each stage of the product development cycle. Addressing issues during the design phase can save you up to 100 times the cost of fixing them after release.

Overcoming Testing Challenges

We understand the complexities and challenges involved in testing today’s sophisticated electronics. Keeping pace with ever-evolving industry standards, testing intricate electronic assemblies, and managing the cost and time constraints associated with testing can be daunting. Qual-Pro’s expertise and advanced technology help you overcome these hurdles, streamlining the testing process and delivering accurate results efficiently.

Qual-Pro’s Legacy of Testing Excellence

With over 50 years of experience in electronics manufacturing, Qual-Pro has honed its testing capabilities to perfection. Our team of certified test engineers brings a wealth of knowledge and expertise to every project. We combine proven methodologies with cutting-edge technology to ensure your products are tested to the most rigorous standards. Our ISO, AS9100, and IPC certifications further validate our dedication to quality and precision.

Thorough testing is not just a quality control measure; it’s a strategic investment that safeguards your brand reputation, enhances customer loyalty, and drives long-term success. Qual-Pro’s test engineering and automatic test development solutions empower you to overcome testing challenges and deliver exceptional products to the market.

By leveraging our US-based engineering expertise for rapid prototyping and NPI, coupled with efficient high-volume production in Thailand, we streamline your product development journey and accelerate your time-to-market.

Our Thailand facility offers significant cost savings due to lower labor costs and access to a robust Asian supply chain. We pass these savings on to you, making your products more competitive in the global marketplace.

Global manufacturing can present challenges like communication barriers, IP protection, and quality control. Qual-Pro mitigates these risks through transparent communication, stringent quality management systems, and a dedicated global program management team.

Yes, we offer comprehensive logistics and shipping services, including direct shipment to your customers in the US and EU, ensuring your products reach their destination on time and in perfect condition.