Bring your electronic products to life with Qual-Pro’s precision PCBA assembly and comprehensive box build services.

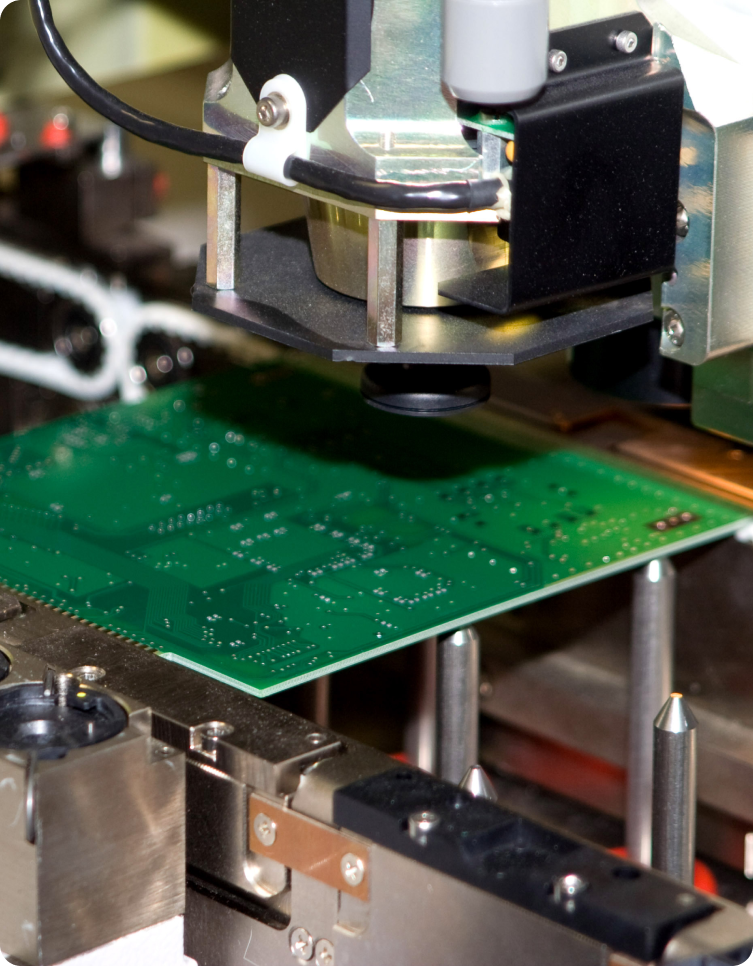

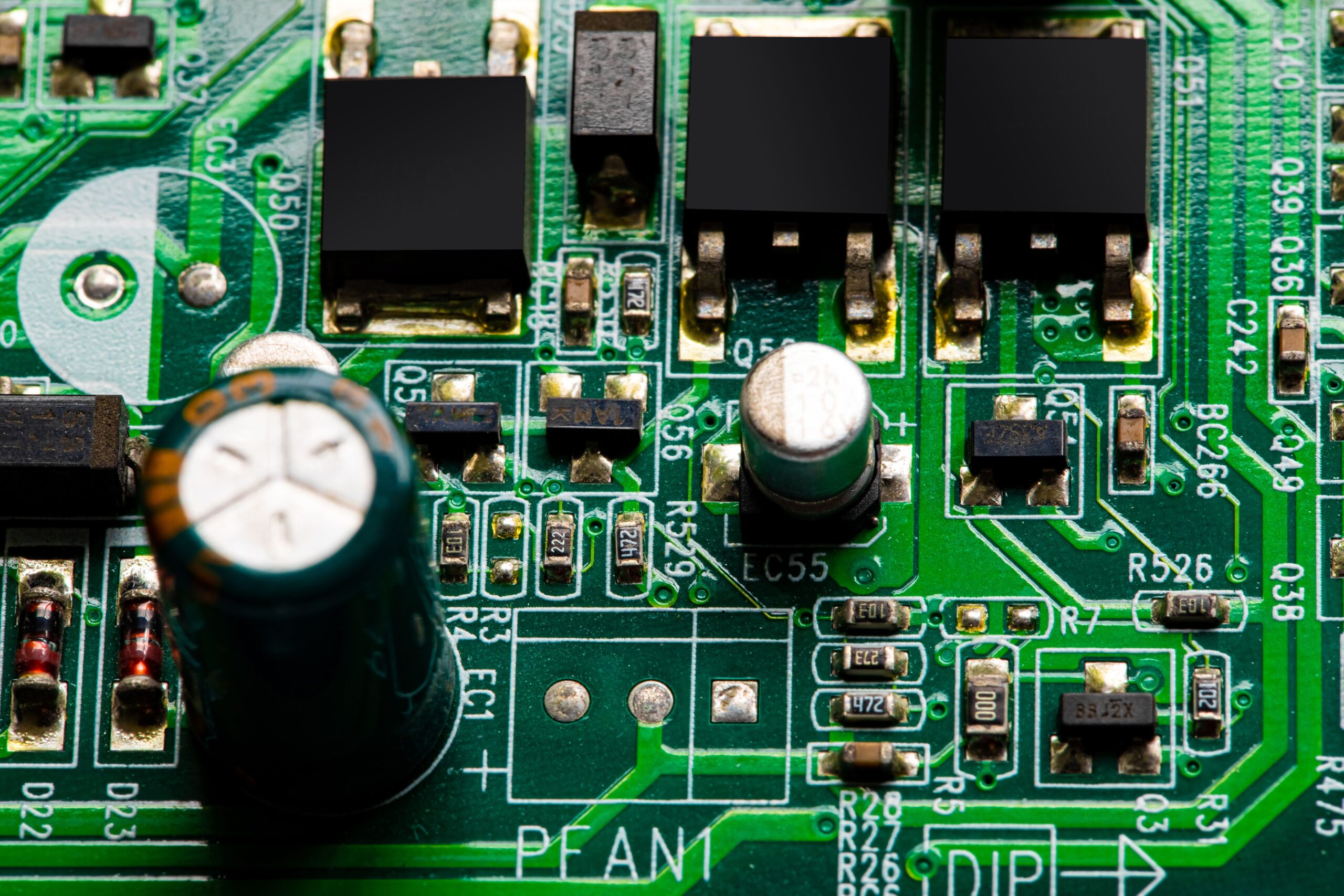

Printed Circuit Board Assembly (PCBA) refers to the precise process of placing and soldering electronic components onto a bare printed circuit board. These components — such as microcontrollers, capacitors, resistors, and connectors — are mounted using advanced technologies like:

The final result is a fully functional circuit board that serves as the operational core of your electronic device. The accuracy of this process directly impacts product performance, reliability, and long-term durability — which is why precision matters at every stage.

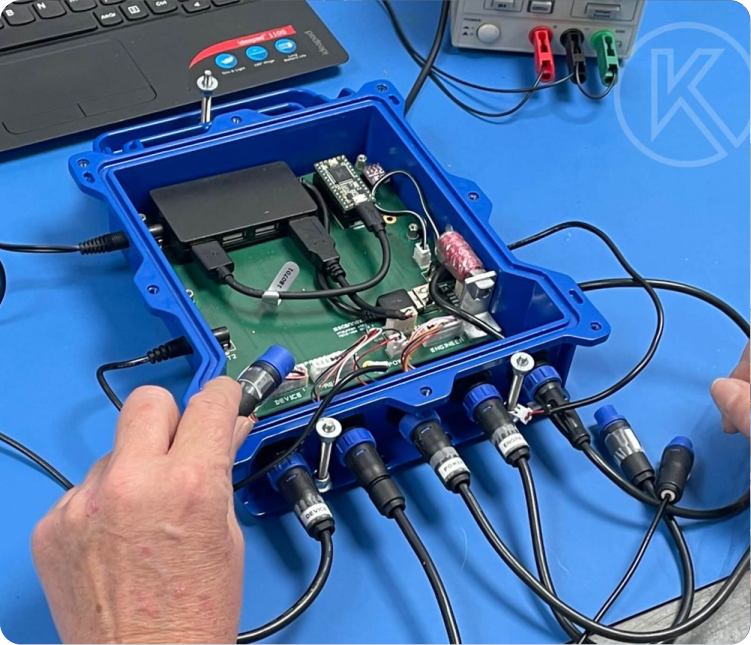

Once PCBA is complete, the product moves into the box build phase — sometimes called system integration or final assembly. Here, fully assembled circuit boards are installed into custom-designed enclosures or housings, along with:

Box build completes the transformation from an assembled PCB to a finished, fully integrated product, ready for end-customer shipment or installation. This stage demands not only technical skill, but also strict process control to ensure repeatable quality, functional integrity, and compliance with customer specifications.

End-to-End Supply Chain Management

We source components, manage inventory, handle logistics, and deliver finished products worldwide — all under a fully documented and auditable quality system.

Precision manufacturing is only as strong as the quality system behind it. At Qual-Pro, every PCBA and box build program is governed by industry-leading certifications, including:

Each unit produced is subjected to rigorous inspection, functionality testing, and documented verification processes to ensure defect-free delivery — regardless of production volume or application complexity.

By consolidating PCBA assembly and box build services under one trusted partner, you eliminate the challenges of coordinating multiple vendors, avoid delays in handoffs between suppliers, and significantly reduce project risk.

From initial engineering review to final packaging and global delivery, Qual-Pro offers a fully integrated manufacturing model that simplifies your product lifecycle — while enhancing quality, consistency, and scalability.

Whether you require low-volume prototypes or high-volume global production, Qual-Pro’s PCBA assembly and box build solutions are engineered to support your unique technical and commercial requirements.

Qual-Pro is committed to providing our customers with the highest quality service throughout the value stream.

Useful Links

Location