In a world increasingly driven by electronics, the importance of a reliable PCB (Printed Circuit Board) cannot be overstated. Whether you’re a startup developing the next wearable tech or a defense contractor designing mission-critical systems, choosing the right PCB Manufacturer in California is a strategic decision. With the state being a hub for innovation, especially in Silicon Valley, California boasts a range of high-quality, technology-forward PCB fabrication and assembly companies.

In this comprehensive guide, we’ll walk you through what makes a top-tier PCB Manufacturer in California, what services to expect, and how to choose the right one for your next project.

Why Choose a PCB Manufacturer in California?

California is home to some of the world’s most innovative industries—semiconductors, medical devices, automotive tech, and defense systems. Working with a PCB Manufacturer in California offers several advantages:

- Faster Turnaround Times: Many California-based PCB companies offer quick-turn PCBs, essential for R&D and prototyping.

- Proximity to Tech Hubs: Being close to Silicon Valley means better communication and reduced shipping times.

- Compliance and Certifications: Top manufacturers in California are often ISO 9001, IPC-A-600, and ITAR certified, ensuring high standards in electronics manufacturing.

- Eco-Conscious Practices: California’s regulations encourage sustainable PCB fabrication and waste management.

Services Offered by PCB Manufacturers in California

When evaluating a PCB Manufacturer in California, it’s important to consider the range of services offered. Leading companies usually provide end-to-end solutions:

1. PCB Design and Layout

Some manufacturers offer in-house PCB design services or collaborate with engineers to optimize board layout, signal integrity, and thermal management.

2. Printed Circuit Board Fabrication

From single-sided to multi-layered boards (up to 40+ layers), California PCB manufacturers provide high-quality printed circuit board fabrication using FR4, Rogers, and other advanced materials.

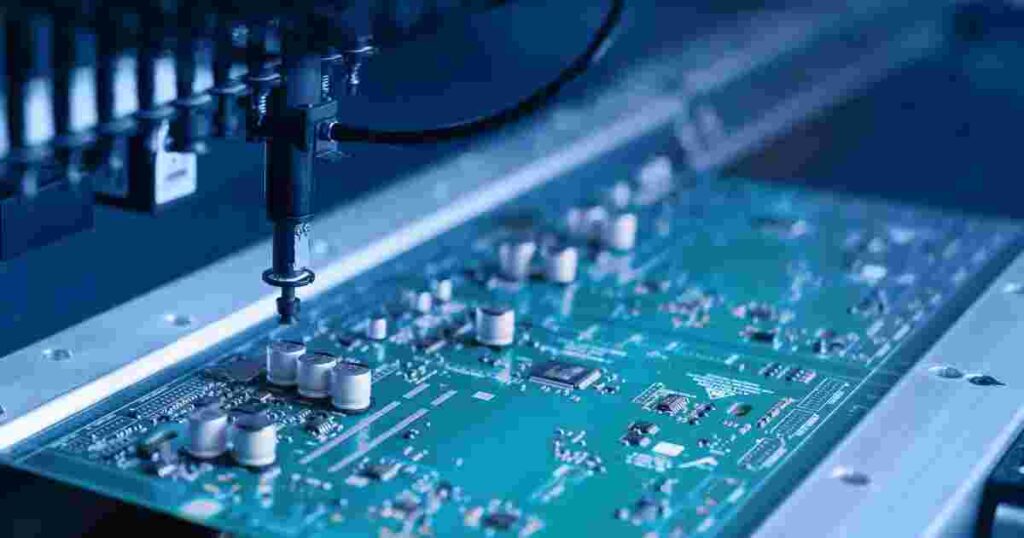

3. PCB Assembly (PCBA)

Top firms offer turnkey PCB assembly, including:

- Surface Mount Technology (SMT)

- Through-hole assembly

- Mixed technology

- BGA and micro-BGA placement

- Conformal coating and encapsulation

4. Prototype PCB Services

Startups and engineers working on new product development benefit from prototype PCB services that allow rapid iteration and testing before full production.

5. Testing and Quality Assurance

Trusted PCB manufacturers in California conduct rigorous inspections, such as:

- AOI (Automated Optical Inspection)

- X-ray inspection

- In-circuit testing (ICT)

- Functional testing

Industries Served by California-Based PCB Companies

● Consumer Electronics

From smartphones to gaming devices, custom PCB services are essential in this high-volume, fast-paced sector.

● Medical Devices

California has a strong med-tech presence, and manufacturers must adhere to strict FDA guidelines and offer medical-grade PCB assembly.

● Aerospace and Defense

Many PCB manufacturers in California are ITAR registered, making them suitable for aerospace and military-grade PCBs that demand durability and precision.

● Automotive

Advanced driver-assistance systems (ADAS), EV battery management systems, and infotainment platforms require robust PCB fabrication with high heat resistance and signal integrity.

● Industrial Automation

PCBs used in robotics, control systems, and sensor networks need to be highly durable and able to handle extreme conditions.

What Sets the Top PCB Manufacturers in California Apart?

● Advanced Capabilities

Look for companies offering multilayer boards, HDI (High-Density Interconnect), flex and rigid-flex circuits, and RF PCBs.

● Certifications and Compliance

Reputable manufacturers hold certifications such as:

- ISO 9001: Quality management systems

- IPC-A-610 & IPC-A-600: Assembly and workmanship

- ITAR: For defense-related manufacturing

- RoHS & REACH: Environmental compliance

● Customer Support and Engineering Consultation

Top manufacturers don’t just fabricate—they collaborate. Their engineering teams offer valuable insights during the design and prototyping stages, saving both time and money.

● On-Time Delivery and Scalability

Speed matters. Many PCB manufacturers in California offer quick-turn PCBs in 24–48 hours for prototypes and flexible timelines for mass production.

How to Choose the Right PCB Manufacturer in California

With so many options, here are key criteria to help you choose the best match for your project:

1. Experience and Track Record

Look for a California PCB manufacturer with a proven portfolio in your industry and client testimonials that highlight reliability and innovation.

2. Technology and Equipment

Modern PCB production requires state-of-the-art equipment. Choose a manufacturer that uses:

- Laser direct imaging (LDI)

- Flying probe testers

- Automated pick-and-place machines

- Reflow ovens and wave soldering systems

3. Material Availability

For niche applications, you may need high-frequency laminates, heavy copper, or RoHS-compliant materials. Verify material options beforehand.

4. Prototyping and Volume Production

Choose a partner who can scale with your growth—from small prototype runs to high-volume production without compromising quality.

5. Transparency and Communication

A quality PCB Manufacturer in California will be transparent about pricing, lead times, tolerances, and changes in design specifications.

Top 5 Questions to Ask Before Choosing a Manufacturer

- Do you offer design and layout consultation?

- What are your standard lead times for prototypes and full runs?

- Which certifications do you hold?

- Can you handle advanced board types like HDI or rigid-flex?

- What quality testing methods do you use on all boards?

Benefits of Local PCB Manufacturing in California

- Quicker Turnarounds: Avoid delays due to customs and international shipping.

- Better Communication: Direct access to your account manager or engineer.

- IP Protection: Reduced risk of intellectual property theft.

- Eco-Friendly Manufacturing: California companies often implement sustainable waste and chemical handling procedures.

Future Trends in PCB Manufacturing

As the electronics landscape evolves, PCB manufacturers in California are investing in:

- AI and automation in inspection and assembly

- Microelectronics and miniaturization for wearables and medical implants

- 5G-ready and RF PCBs for advanced communication technologies

- Smart PCBs embedded with sensors for diagnostics and predictive maintenance

Staying ahead of these trends can significantly reduce your time-to-market and improve your product’s reliability.

Final Thoughts

Finding the right PCB Manufacturer in California can be the key to your product’s success. With advanced technology, rigorous quality control, and close proximity to the heart of the tech industry, California offers some of the best PCB manufacturing services in the world.

Whether you need a prototype PCB, high-volume PCB assembly, or specialized custom PCB services, a reliable California partner ensures your design turns into a fully functional, high-performance product.

By asking the right questions, evaluating technical capabilities, and prioritizing customer service, you can confidently choose a PCB Manufacturer in California that aligns with your goals and technical requirements.