At Qual-Pro, we are your trusted partner in navigating the complexities of product development, ensuring a smooth and successful journey from concept to launch.

Turning your groundbreaking ideas into market-ready products requires more than just engineering expertise—it demands a strategic, streamlined New Product Introduction (NPI) process and the ability to rapidly prototype and validate your designs. At Qual-Pro, we are your trusted partner in navigating the complexities of product development, ensuring a smooth and successful journey from concept to launch.

As your trusted manufacturing partner, we’re dedicated to exceeding your expectations with superior quality and end-to-end solutions.

The NPI process is the structured roadmap that guides your product’s evolution, from initial concept to full-scale production and launch. It’s a multifaceted approach involving planning, design, engineering, prototyping, testing, and manufacturing.

At Qual-Pro, our seasoned NPI experts guide you through each phase, leveraging over five decades of experience and proven methodologies to minimize risks, optimize costs, and accelerate your time-to-market. We’re not just a service provider; we’re your strategic partner in bringing your vision to life.

Why a Structured NPI Process is Crucial

Research by the Product Development and Management Association (PDMA) shows that companies with a well-defined NPI process achieve a 30% higher success rate in new product launches. A robust NPI strategy mitigates the financial risks associated with launching a flawed product, safeguarding your investment and enhancing your chances of market success.

Prototyping: The Bridge to Manufacturing

Prototyping is an integral part of NPI, allowing you to create tangible representations of your product, test its functionality, gather valuable user feedback, and fine-tune your design before mass production. It’s a powerful tool for validating concepts, identifying potential issues, and ensuring manufacturability.

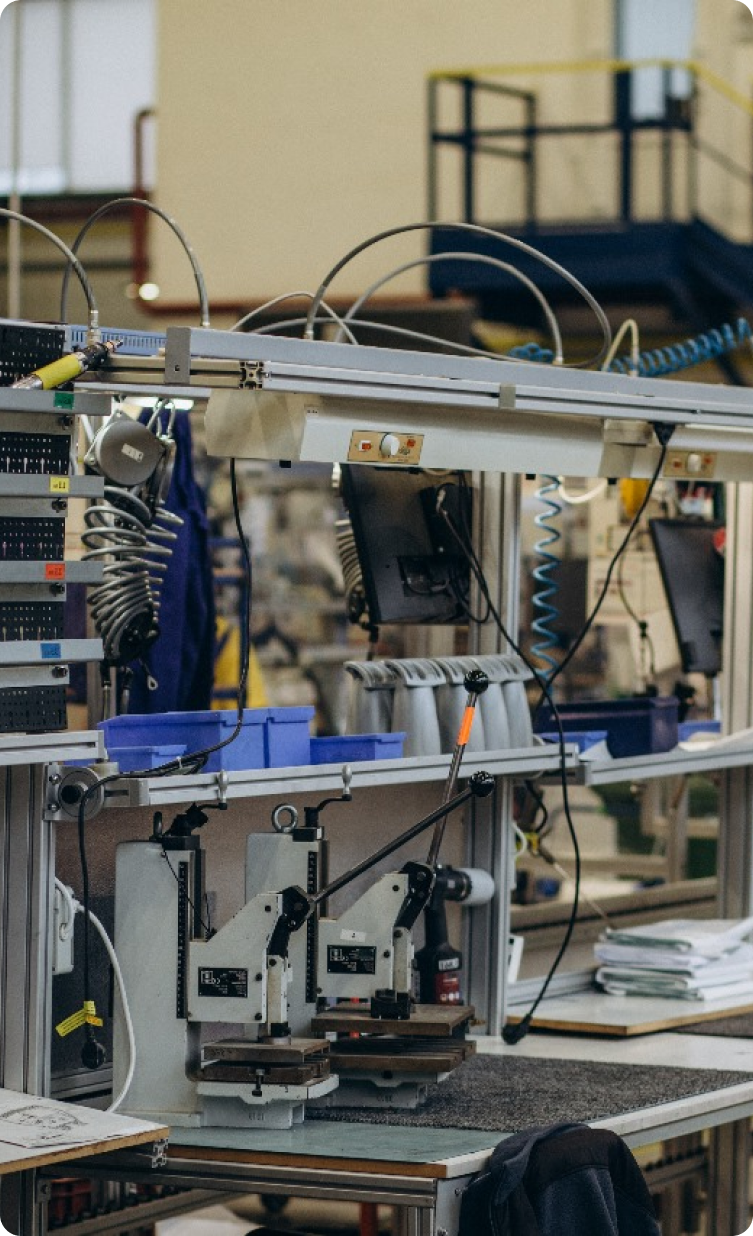

Qual-Pro offers a comprehensive suite of NPI and prototyping services meticulously designed to accelerate your product development and ensure a triumphant market entry. Our collaborative approach, coupled with state-of-the-art facilities and expert engineers, streamlines the journey from idea to a market-ready product.

Our End-to-End NPI & Prototyping Solutions:

By leveraging our US-based engineering expertise for rapid prototyping and NPI, coupled with efficient high-volume production in Thailand, we streamline your product development journey and accelerate your time-to-market.

Our Thailand facility offers significant cost savings due to lower labor costs and access to a robust Asian supply chain. We pass these savings on to you, making your products more competitive in the global marketplace.

Global manufacturing can present challenges like communication barriers, IP protection, and quality control. Qual-Pro mitigates these risks through transparent communication, stringent quality management systems, and a dedicated global program management team.

Yes, we offer comprehensive logistics and shipping services, including direct shipment to your customers in the US and EU, ensuring your products reach their destination on time and in perfect condition.