In today’s electronics-driven world, devices are becoming smaller, more powerful, and often expected to perform under harsh environmental conditions. As a result, protecting the delicate circuitry of printed circuit boards (PCBs) is more crucial than ever. One of the most reliable ways to achieve this is through Conformal Coating Solutions—a critical technology that ensures the longevity, safety, and functionality of electronic assemblies.

This article explores everything you need to know about Conformal Coating Solutions—their types, key applications, and long-term benefits. Whether you’re an electronics manufacturer, an engineer, or just curious about PCB protection, this comprehensive guide will give you insight into why these coatings matter.

What Are Conformal Coating Solutions?

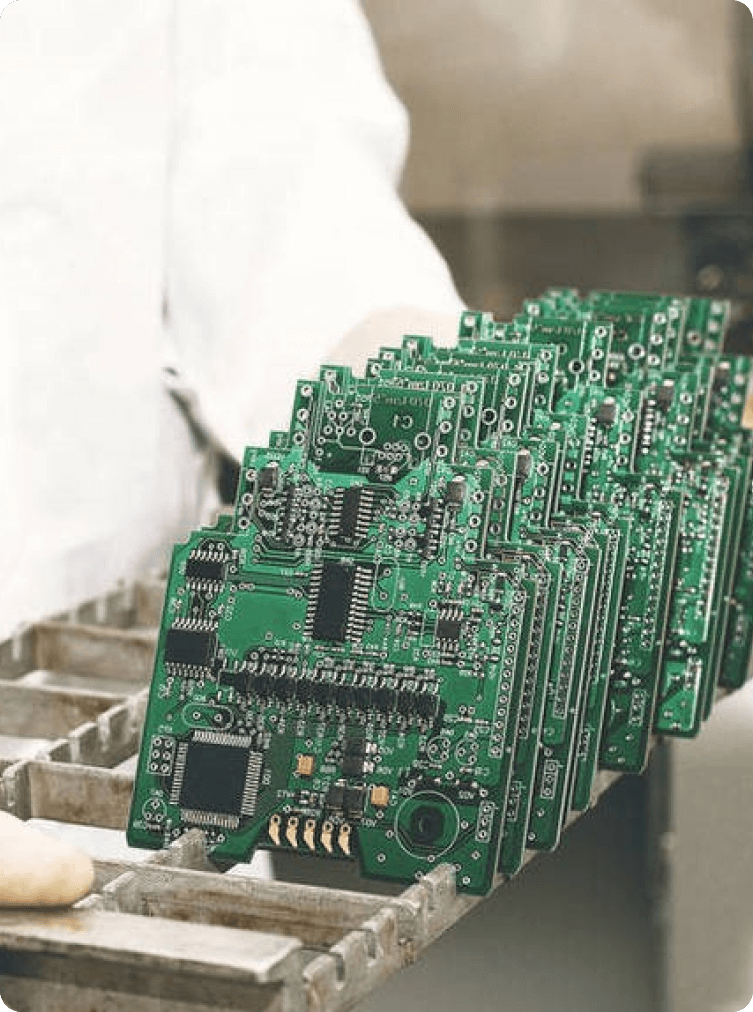

Conformal Coating Solutions are specialized protective films applied to PCBs and other electronic components. These coatings “conform” to the surface of the circuit board, creating a thin, transparent barrier that guards against environmental threats such as moisture, dust, chemicals, temperature extremes, and mechanical stress.

The coatings are typically applied in layers ranging from 25 to 250 micrometers and are used in industries like automotive, aerospace, telecommunications, and medical devices. Without these protective layers, electronic devices are highly vulnerable to corrosion, short circuits, and premature failure.

Why Are Conformal Coating Solutions Important?

Modern electronics often operate in unpredictable or extreme conditions. Devices may be exposed to high humidity, salt fog, corrosive gases, or dust—all of which can compromise circuit integrity.

Key Benefits of Conformal Coating Solutions:

- Moisture Resistance: Prevents corrosion and electrical failures caused by condensation or humidity.

- Chemical Protection: Shields circuits from chemical vapors, oils, and corrosive gases.

- Dust and Debris Blocker: Keeps fine particles from interfering with electrical signals.

- Thermal Stability: Enhances performance under fluctuating temperatures.

- Extended Product Life: Increases the durability and service life of PCBs.

- Improved PCB Reliability: Ensures consistent functionality over time in mission-critical applications.

In short, Conformal Coating Solutions act like armor for your electronics.

Types of Conformal Coating Solutions

Not all coatings are created equal. The ideal conformal coating depends on your application, performance needs, and environmental challenges. Below are the most commonly used types:

1. Acrylic Coatings

Acrylic is one of the most popular materials due to its ease of application and removal. It provides excellent moisture resistance and dielectric strength but offers limited chemical and abrasion resistance.

- Pros: Cost-effective, easy to apply/remove, transparent

- Cons: Less chemical and heat resistance

2. Silicone Coatings

Silicone is ideal for high-temperature and high-humidity environments. It offers outstanding flexibility, making it suitable for applications where thermal expansion and contraction are a concern.

- Pros: High thermal stability, flexible, resistant to UV and chemicals

- Cons: Difficult to remove, more expensive

3. Polyurethane Coatings

Polyurethane coatings provide strong chemical and abrasion resistance. They are commonly used in automotive and industrial applications where exposure to oils and solvents is expected.

- Pros: Excellent chemical and abrasion resistance

- Cons: Difficult to rework, slow drying

4. Epoxy Coatings

Epoxy is a rigid and durable coating often used in applications where maximum chemical protection is required. It forms a hard shell around the circuit board but can be brittle.

- Pros: Strong barrier against chemicals and moisture

- Cons: Limited flexibility, difficult to remove

5. Parylene Coatings

Parylene is a vapor-deposited, ultra-thin coating known for its uniformity and superior barrier properties. It’s widely used in medical, aerospace, and military electronics.

- Pros: Ultra-thin, highly uniform, chemically inert

- Cons: Requires specialized equipment, expensive

Each of these Conformal Coating Solutions has unique advantages and trade-offs, making the selection process critical to long-term device performance.

Application Methods

There are several ways to apply Conformal Coating Solutions, and the choice depends on the scale, complexity, and required precision of the coating.

Common Methods Include:

- Brushing: Manual application for touch-ups or small runs

- Spraying: Ideal for medium production volumes; can be automated

- Dipping: Circuit boards are submerged; great for high-volume production

- Selective Coating: Robotic systems apply coatings precisely, avoiding connectors and other no-coat zones

- Vapor Deposition: Used for parylene coatings; offers highly uniform coverage

Choosing the right method is just as important as choosing the right material. Improper application can lead to poor adhesion, air bubbles, or incomplete coverage.

Common Industries Using Conformal Coating Solutions

The demand for Conformal Coating Solutions spans across many sectors where environmental protection is essential:

- Aerospace & Defense: Ensures circuit performance under altitude, vibration, and thermal stress

- Automotive: Protects vehicle electronics from oil, grime, and rapid temperature changes

- Medical Devices: Safeguards sensitive electronics in implantables and diagnostic equipment

- Consumer Electronics: Extends the lifespan of smartphones, wearables, and smart home devices

- Industrial Automation: Guards control systems in corrosive and dusty factory environments

Wherever precision electronics are used, Conformal Coating Solutions are likely to be a vital part of the design and manufacturing process.

Key Considerations When Selecting a Coating

Choosing the best coating involves more than picking a material. Here are a few important factors:

- Operating Environment: High humidity, chemicals, UV exposure, or vibration?

- Electrical Performance: Will the coating affect signal transmission?

- Serviceability: Do you need to rework or repair the board in the future?

- Compliance: Does the coating meet industry standards like IPC-CC-830 or MIL-I-46058C?

A careful assessment ensures you’re not under- or over-engineering the solution.

Future Trends in Conformal Coating Solutions

As electronics continue to shrink and performance demands grow, Conformal Coating Solutions are evolving too. Future innovations include:

- Smart coatings that can self-heal minor damage

- Eco-friendly formulations with lower VOC emissions

- Nano-coatings that provide superior protection at the microscopic level

- AI-driven selective coating systems for faster and more precise applications

Manufacturers are investing heavily in R&D to create more efficient, sustainable, and cost-effective protective technologies.

Final Thoughts

In the world of electronics, performance is everything—and so is protection. Conformal Coating Solutions offer the first line of defense against environmental and mechanical threats that could compromise your PCB’s functionality and reliability. From simple acrylic coatings to advanced parylene applications, the right coating can extend the life of your product and reduce maintenance and failure rates.

For engineers, designers, and manufacturers, understanding the types, uses, and benefits of Conformal Coating Solutions isn’t just technical knowledge—it’s a competitive advantage.