Qual-Pro’s expert conformal coating services safeguard your valuable electronics from harsh conditions.

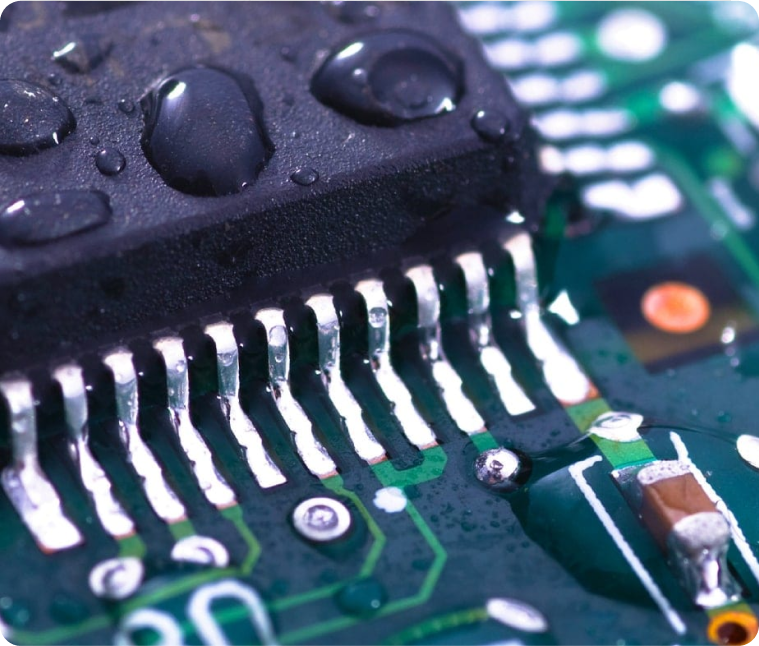

Qual-Pro’s expert conformal coating services safeguard your valuable electronics from harsh conditions. Our precise application and diverse coating options ensure unparalleled protection and performance, empowering your products to thrive in any environment.

As your trusted manufacturing partner, we’re dedicated to exceeding your expectations with superior quality and end-to-end solutions.

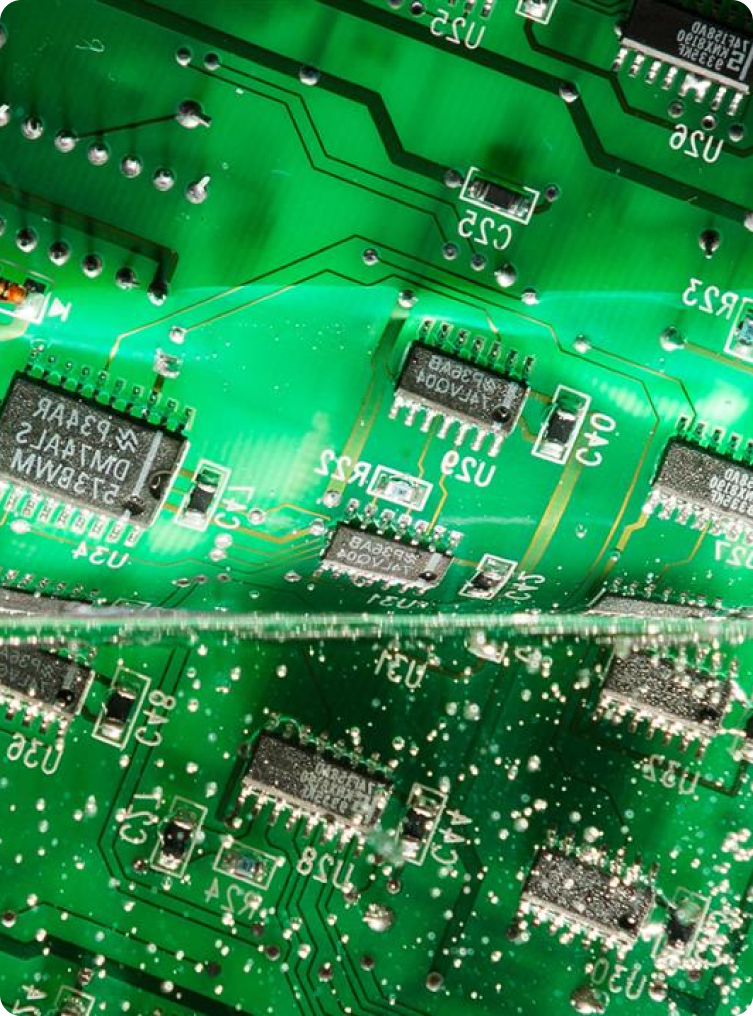

We provide a full suite of conformal coating services, expertly tailored to your unique needs and industry requirements.

Removal & Rework: Our experts can safely and efficiently remove conformal coating when needed, facilitating rework or repair processes without compromising your product’s integrity.

By leveraging our US-based engineering expertise for rapid prototyping and NPI, coupled with efficient high-volume production in Thailand, we streamline your product development journey and accelerate your time-to-market.

Our Thailand facility offers significant cost savings due to lower labor costs and access to a robust Asian supply chain. We pass these savings on to you, making your products more competitive in the global marketplace.

Global manufacturing can present challenges like communication barriers, IP protection, and quality control. Qual-Pro mitigates these risks through transparent communication, stringent quality management systems, and a dedicated global program management team.

Yes, we offer comprehensive logistics and shipping services, including direct shipment to your customers in the US and EU, ensuring your products reach their destination on time and in perfect condition.