In the competitive world of electronic manufacturing, precision and quality are non-negotiable. As printed circuit boards (PCBs) become smaller, faster, and more complex, manufacturers face increasing pressure to catch even the tiniest defects before products reach customers. Enter Automated Optical Inspection (AOI)—a game-changing technology that’s revolutionizing how the industry ensures quality and reliability.

But what exactly is Automated Optical Inspection, and why is it considered essential in today’s PCB production lines? In this guide, we’ll explore the technology, how it works, its benefits, and why integrating AOI into your workflow is critical for success in 2025 and beyond.

What is Automated Optical Inspection?

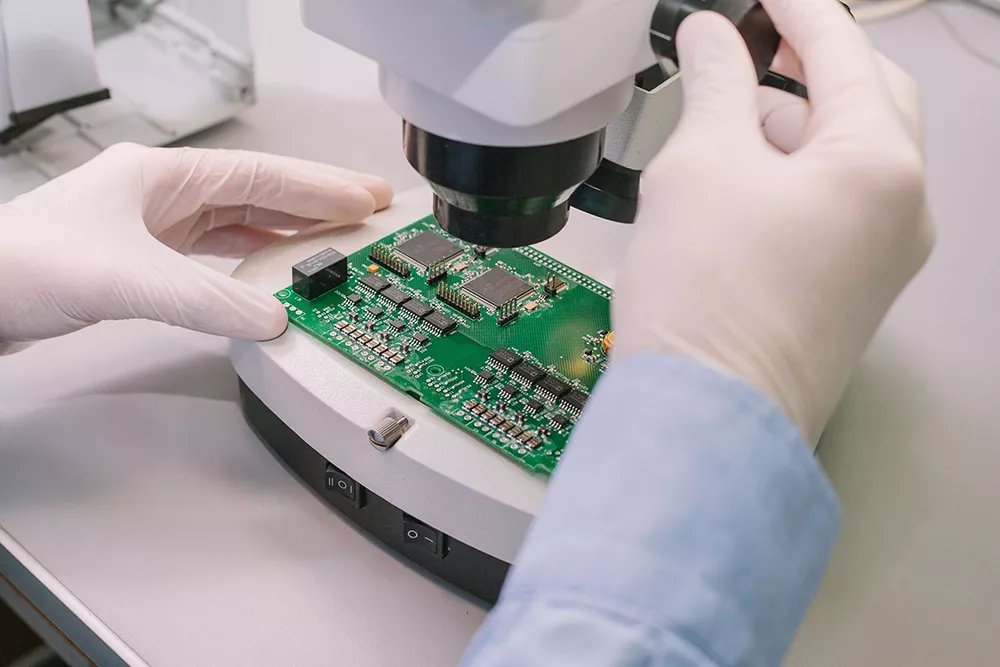

Automated Optical Inspection (AOI) is a non-contact visual inspection technique used to detect defects in printed circuit boards (PCBs) during or after the assembly process. AOI systems use high-resolution cameras and advanced image processing algorithms to scan PCBs for various issues such as missing components, soldering defects, incorrect polarity, and misalignments.

AOI systems play a pivotal role in surface-mount technology (SMT) assembly lines, ensuring that both placement and soldering processes meet strict quality control standards. Whether integrated as inline or offline inspection stations, these systems are essential tools for maintaining production efficiency and customer satisfaction.

How Automated Optical Inspection Works

The process of Automated Optical Inspection can be broken down into a few key steps:

- Image Capture: High-speed cameras scan the PCB using visible light or infrared to capture detailed images of the board.

- Reference Comparison: The captured images are compared to a “golden board” reference file, or to CAD data, which contains the correct layout and component placement.

- Defect Detection: AOI software analyzes the differences between the scanned board and the reference to detect any anomalies. Common issues identified include:

- Solder bridges

- Component misalignment

- Missing or extra components

- Incorrect orientation or polarity

- Tombstoning of resistors and capacitors

- Reporting and Classification: Once identified, the defects are categorized and displayed to the operator for review. Depending on the system, AOI may also integrate with MES (Manufacturing Execution Systems) for traceability and real-time analytics.

Why AOI is Crucial in Modern PCB Manufacturing

In the past, manual visual inspection was widely used for quality control. However, human error, fatigue, and time constraints made it increasingly unreliable—especially with the miniaturization of components and the complexity of modern boards. This is where Automated Optical Inspection truly shines.

Key Benefits of AOI:

1. High Accuracy in Defect Detection

AOI systems can detect defects as small as a few microns. This level of precision is vital in detecting soldering flaws or component misalignments that could go unnoticed in manual inspection. The result? A dramatic reduction in defect escape rates and improved product reliability.

2. Speed and Efficiency

Unlike manual inspection, AOI systems can scan hundreds of boards per hour with consistent accuracy. Whether operating in-line after solder paste application, component placement, or reflow soldering, AOI reduces inspection time and keeps production flowing smoothly.

3. Consistent and Repeatable Results

Human inspectors may vary in their judgments, especially under long working hours. AOI systems, however, provide repeatable and standardized inspection, removing subjectivity and ensuring consistent quality across batches.

4. Reduced Rework and Cost

By catching defects early in the production cycle, Automated Optical Inspection reduces the amount of costly rework or scrap. Early detection helps isolate issues to specific machines or processes, allowing for quicker root-cause analysis and corrective action.

5. Data-Driven Process Improvement

Modern AOI machines are not just detectors—they are data collectors. By analyzing defect trends, manufacturers can identify recurring issues in the assembly process. This leads to continuous improvement in manufacturing quality and operational efficiency.

Types of AOI Systems

There are various AOI systems available, each suited for different stages of the PCB manufacturing process:

1. 2D AOI Systems

These are the most common and affordable. They use a single camera to capture a flat image of the board. While effective for many applications, they may struggle to detect certain 3D-related defects like lifted leads.

2. 3D AOI Systems

These advanced systems use multiple cameras and projectors to create a three-dimensional image of the PCB. They provide more accurate inspection of solder joints and height-based measurements, making them ideal for surface-mount technology (SMT) lines with tight tolerances.

3. Inline vs. Offline AOI

- Inline AOI: Integrated into the production line and provides real-time inspection as PCBs move through the process.

- Offline AOI: Used for random sample inspection or low-volume production where inline systems may not be cost-effective.

Common PCB Defects Detected by AOI

Automated Optical Inspection can identify a wide variety of faults that might otherwise compromise PCB function. Some of the most common include:

- Solder Bridges – Unintended connections between two conductors

- Tombstoning – Component standing upright due to uneven soldering

- Missing Components – Skipped placements during SMT process

- Incorrect Component Orientation – Polarity-sensitive components flipped

- Cold Solder Joints – Incomplete melting leading to poor electrical connections

- Foreign Objects – Debris or contaminants on the board

Detecting and resolving these issues early prevents functional failures and boosts end-user trust.

Integration with Other Inspection Technologies

While Automated Optical Inspection is powerful, it is often used in conjunction with other inspection systems for a comprehensive quality control strategy:

- Solder Paste Inspection (SPI): Verifies the volume and alignment of solder paste before component placement.

- X-Ray Inspection (AXI): Detects hidden defects, especially in Ball Grid Array (BGA) packages where optical inspection is limited.

- Functional Testing (FCT): Confirms that the board works as intended by applying power and running tests.

Together, these tools create a layered inspection process that leaves little room for error.

Future Trends in AOI Technology

As PCB inspection technology evolves, AOI is becoming smarter and more efficient:

1. AI and Machine Learning

Modern AOI systems are beginning to incorporate AI to reduce false calls and learn from inspection data. These intelligent algorithms can distinguish between acceptable variations and true defects, improving both accuracy and speed.

2. Cloud-Based Reporting

Data collected from AOI machines is increasingly stored and analyzed in the cloud, allowing for better traceability, global reporting, and process optimization.

3. Industry 4.0 Integration

AOI is becoming part of a larger smart factory ecosystem where inspection results are fed into manufacturing systems for automatic adjustments and alerts.

Choosing the Right AOI System

When selecting an Automated Optical Inspection system, consider the following:

- Board Complexity: High-density boards benefit more from 3D AOI systems.

- Production Volume: Inline systems are best for high-speed production; offline suits smaller batches.

- Budget: While 3D AOI is more accurate, it also comes with higher costs.

- Defect Types: Choose systems optimized for the types of defects most likely in your process.

Investing in the right AOI system pays off in improved yields, fewer returns, and enhanced customer satisfaction.

Final Thoughts

As electronics become increasingly advanced, so must the methods we use to ensure their quality. Automated Optical Inspection has become a foundational technology in modern PCB manufacturing. With its unmatched accuracy, consistency, and efficiency, AOI helps manufacturers reduce defects, improve production speed, and deliver reliable products to market.

Incorporating Automated Optical Inspection into your quality control process is no longer optional—it’s essential. It not only safeguards your brand reputation but also enhances your competitive edge in an industry where precision is everything.

If you’re looking to future-proof your production line, now is the time to explore how AOI can elevate your PCB quality to world-class standards.