In today’s world of miniaturized and sensitive electronics, protecting printed circuit boards (PCBs) from environmental hazards is critical. Whether you’re manufacturing consumer electronics, automotive systems, or aerospace components, ensuring long-term reliability is essential. That’s where conformal coatings come into play.

Among the most widely used conformal coatings, two materials dominate the field: acrylic and silicone. Each has unique properties, advantages, and limitations. So, when it comes to Acrylic vs Silicone, which conformal coating solution is right for you?

Let’s explore the differences in detail to help you make an informed choice based on your specific application requirements.

What Is Conformal Coating and Why It Matters

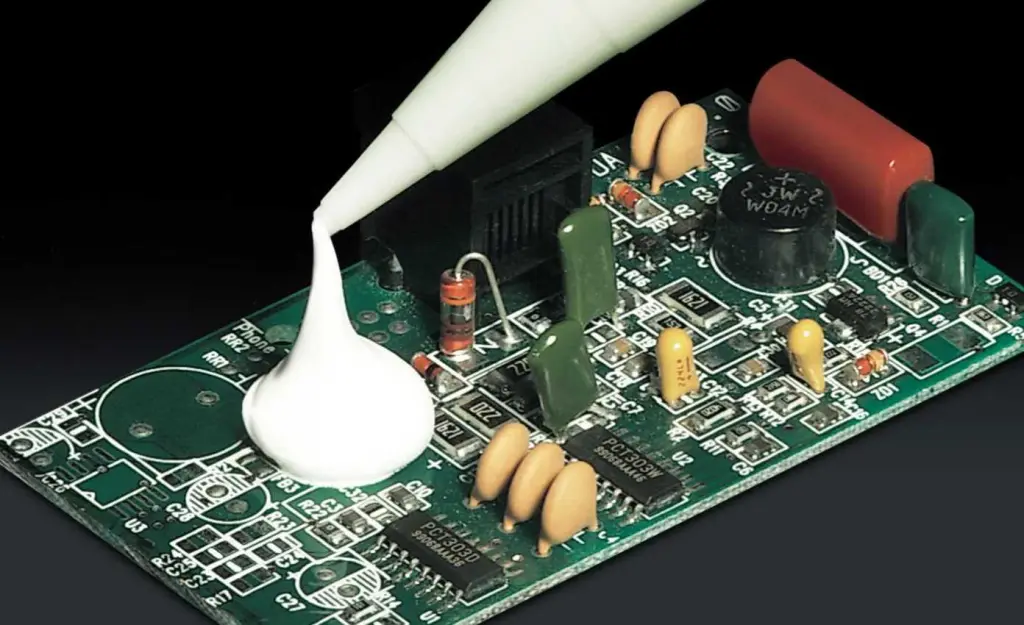

Before diving into the comparison, it’s important to understand what conformal coating is. Conformal coating is a protective, non-conductive film applied to electronic circuit boards to guard against moisture, dust, chemicals, corrosion, and thermal stress. These coatings extend the life of electronic components and prevent failure in harsh environments.

Among the various types—urethane, epoxy, parylene—acrylic and silicone are the most popular due to their versatile properties and ease of application.

Acrylic Conformal Coating: Benefits and Limitations

Acrylic coatings are made from polymers that offer a fast-drying and cost-effective solution for many general-purpose applications. They are typically chosen for their clarity, ease of repair, and excellent moisture resistance.

Advantages of Acrylic Coatings:

- Fast Curing Time: Acrylic coatings cure quickly at room temperature, making them ideal for high-volume production lines.

- Easy Reworkability: Acrylic coatings can be easily removed with common solvents for inspection or repair.

- Excellent Humidity Resistance: They perform well in humid environments and protect against moisture and mildew.

- Cost-Effective: Acrylics are generally more budget-friendly compared to silicones.

Limitations of Acrylic Coatings:

- Low Thermal Resistance: Acrylics typically withstand temperatures only up to 125°C, which limits their use in high-temperature environments.

- Moderate Chemical Resistance: While they offer decent protection, they don’t hold up well against aggressive chemicals and solvents.

- Poor Flexibility: Acrylic coatings can crack under mechanical stress or vibration, making them less suitable for dynamic applications.

Silicone Conformal Coating: Benefits and Limitations

Silicone coatings are elastomeric materials known for their superior thermal stability, flexibility, and resistance to harsh chemicals. They’re widely used in aerospace, automotive, and other mission-critical applications.

Advantages of Silicone Coatings:

- High Thermal Stability: Silicone coatings can withstand temperatures ranging from -55°C to +200°C, making them perfect for extreme environments.

- Superior Chemical Resistance: They resist oils, solvents, ozone, and corrosive agents.

- Highly Flexible: Their rubbery nature allows them to absorb mechanical shocks and vibration without cracking.

- Excellent Moisture and UV Resistance: They offer robust protection in outdoor and marine environments.

Limitations of Silicone Coatings:

- Difficult to Remove: Reworking or inspecting components coated with silicone is more challenging due to its strong adhesion.

- Longer Curing Time: Some silicone coatings require heat curing, which may slow down production.

- Higher Cost: Silicone coatings tend to be more expensive, both in raw materials and processing.

Acrylic vs Silicone: Side-by-Side Comparison

To simplify the decision-making process, here is a quick comparison chart:

| Feature | Acrylic Coating | Silicone Coating |

|---|---|---|

| Moisture Resistance | Good | Excellent |

| Chemical Resistance | Moderate | High |

| Thermal Resistance | Up to 125°C | Up to 200°C |

| Flexibility | Low to Moderate | High |

| UV Resistance | Fair | Excellent |

| Ease of Repair | Easy | Difficult |

| Curing Time | Fast (air dry) | Slow (may require heat) |

| Cost | Lower | Higher |

| Application Environment | General-purpose | Harsh and extreme |

This side-by-side comparison highlights the core differences when choosing between Acrylic vs Silicone.

Use Case Scenarios: When to Choose Each Coating

When to Use Acrylic Coating:

- Low-to-moderate temperature environments

- Applications with a high need for fast throughput and reworkability

- Budget-sensitive projects

- Indoor electronics with minimal chemical exposure

Example applications: Consumer electronics, home appliances, and basic industrial controls.

When to Use Silicone Coating:

- Extreme thermal cycling environments

- High-vibration or outdoor conditions

- Projects that involve frequent exposure to chemicals or UV rays

- Aerospace, automotive, and defense systems

Example applications: Engine control modules, satellite systems, offshore equipment.

Environmental and Regulatory Considerations

In the ongoing battle of Acrylic vs Silicone, environmental factors also play a role. VOC emissions, RoHS compliance, and safe disposal are key points to evaluate.

- Acrylics typically emit more VOCs during application, but they are easier to handle in terms of disposal.

- Silicones, while more inert post-cure, may require additional precautions during processing and removal.

Choosing a coating that meets your regulatory obligations while aligning with your sustainability goals is critical.

Industry Trends and Innovation

With the rise of electric vehicles, 5G networks, and compact IoT devices, the need for high-performance conformal coatings is only growing.

Some manufacturers now offer hybrid coatings that combine the benefits of both materials. Advanced formulations can deliver the reworkability of acrylics with the temperature tolerance of silicones. However, such coatings come at a premium and may require specialized application methods.

So, in the ongoing Acrylic vs Silicone debate, innovation continues to blur the lines—but the core strengths of each material remain.

Final Thoughts: Choosing the Right Coating for Your Needs

When evaluating Acrylic vs Silicone conformal coatings, there is no one-size-fits-all solution. The ideal choice depends on your:

- Application environment

- Thermal and mechanical stress tolerance

- Chemical exposure levels

- Budget constraints

- Production speed and scalability

If you’re looking for a fast, affordable, and easily reworkable solution, acrylic coatings may be your best option. However, for long-term durability in extreme environments, silicone coatings offer unmatched protection.

By understanding the strengths and limitations of each, you can ensure the right balance between performance, cost, and reliability.