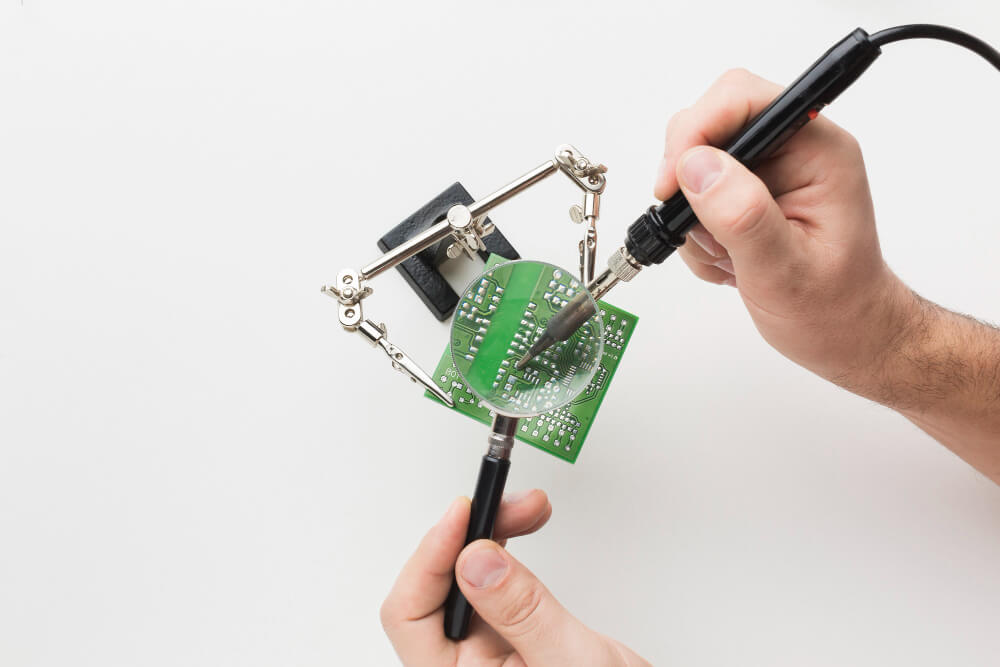

In the world of electronics, manufacturing, and repairs, having the right soldering equipment can be the difference between flawless functionality and recurring issues. Whether you’re a hobbyist tinkering with circuits or a professional technician working on advanced PCB boards, using powerful and reliable tools is non-negotiable. Today’s market offers a range of soldering equipment designed to deliver power, precision, and performance to meet the demands of modern electronics.

In this article, we will explore what makes soldering equipment powerful, how to choose the best tools for your needs, and what features professionals and DIYers should look for in top-tier soldering setups.

Why Powerful Soldering Equipment Matters

In any soldering task, consistency and temperature stability are essential. Powerful soldering equipment ensures quick heating, precise temperature control, and excellent thermal recovery, all of which result in clean, reliable joints.

Low-powered tools often struggle to maintain the correct heat level, especially when dealing with multilayered boards or large metal surfaces. This inconsistency can lead to cold joints, damage to components, and frequent tool replacements. On the other hand, high-performance soldering equipment ensures efficiency, durability, and accuracy.

Types of Soldering Equipment

Understanding the variety of tools available is the first step toward making an informed decision. Let’s take a look at the most commonly used soldering equipment:

1. Soldering Irons

The most basic yet widely used soldering tool, a soldering iron is ideal for simple electronic work. Models range from 15W to over 100W, and the more powerful ones are best for heavy-duty tasks. Look for temperature control soldering irons that allow you to adjust heat settings based on the task at hand.

2. Soldering Stations

A professional soldering station combines a soldering iron with a control unit that provides precise temperature management, digital displays, and sometimes additional tools like hot air guns. These are ideal for frequent users who need versatility and power in a single setup.

3. Hot Air Rework Stations

Essential for SMD (surface mount device) repairs, these stations blow hot air to melt solder, allowing you to remove or place tiny components with ease. Combined with soldering equipment, they form a complete solution for advanced electronics work.

4. Soldering Guns

Used primarily for heavy-gauge wires and metalwork, soldering guns are high-powered tools that heat up quickly and offer rapid cooling. They’re perfect for automotive or large-scale metal assembly work.

Key Features of Powerful Soldering Equipment

If you’re serious about electronics or repairs, investing in soldering equipment with the following features is crucial:

1. Adjustable Temperature Control

Different components require different temperatures. A temperature-controlled soldering iron lets you match the heat to the job, preventing component damage and ensuring a clean joint.

2. Quick Heat-Up Time

Time is money, especially in production environments. Quality soldering equipment heats up rapidly and maintains consistent temperatures for uninterrupted workflow.

3. High Thermal Recovery

This ensures that your iron doesn’t cool down drastically when applied to a surface, maintaining optimal performance during extended usage.

4. Ergonomic Design

Comfort is critical for precision. Lightweight handles, heat-resistant materials, and anti-slip grips reduce hand fatigue and improve accuracy during long sessions.

5. Safety Features

From automatic shut-off systems to heat-resistant casings, modern soldering tools incorporate several features to ensure user safety.

Applications That Demand High-Powered Soldering Tools

Not all soldering tasks are created equal. Certain applications require more power, greater temperature stability, and advanced features.

– PCB Assembly and Repairs

Modern PCBs are complex and often use SMD components. For accurate and damage-free work, a professional soldering station with micro-soldering capabilities is essential.

– Automotive Electronics

In cars, where components are often larger and tougher, only powerful soldering machines can provide the heat and durability required for long-lasting bonds.

– Jewelry Making and Metalwork

While not traditional electronics, soldering is crucial in jewelry and custom metal crafting. These applications need tools with broader temperature ranges and stronger wattage.

– Robotics and Prototyping

From Arduino boards to custom sensors, robotics requires highly adaptable soldering equipment that can switch between delicate and rugged tasks seamlessly.

Maintenance Tips for Long-Lasting Equipment

Investing in quality soldering equipment is just the first step. Proper care ensures your tools remain effective for years to come.

- Clean Tips Regularly: Oxidized tips can ruin joints and damage components. Use a brass wire cleaner or sponge frequently.

- Use the Right Tip for the Job: Wide tips are good for large joints, while needle tips are best for small, detailed work.

- Turn Off When Not in Use: Even though many tools have auto shut-off, it’s good practice to power down when idle.

- Store Properly: Use tip protectors and store in a cool, dry environment to prevent rust and degradation.

How to Choose the Best Soldering Equipment for You

Your ideal soldering equipment depends on how often you use it, what kind of projects you handle, and your budget. Here’s a quick comparison to help guide your decision:

| Feature | Basic Iron | Station | Rework Station | Gun |

|---|---|---|---|---|

| Best for Beginners | ✅ | ✅ | ❌ | ❌ |

| Temperature Control | ❌ | ✅ | ✅ | ❌ |

| SMD Compatibility | ❌ | ✅ | ✅ | ❌ |

| Heavy-Duty Metalwork | ❌ | ❌ | ❌ | ✅ |

Conclusion

Whether you’re building a new prototype or fixing a motherboard, the right soldering equipment can significantly enhance the quality and speed of your work. From temperature control soldering irons to full-fledged professional soldering stations, powerful tools provide the reliability and performance that both DIY enthusiasts and seasoned professionals need.

Investing in quality soldering equipment ensures clean, long-lasting joints, reduces the risk of damage, and improves your overall efficiency. Don’t settle for less—power, precision, and durability should be your top priorities when choosing your next soldering tool.

At Qual-Pro, we offer high-performance soldering equipment built for modern electronics, repair work, and advanced manufacturing needs. Our solutions are engineered for durability, precision, and consistent power—helping you deliver flawless results every time.